Addressing a NHQA feedback report: opportunities for improvement

Receiving a NHQA feedback report can result in a freeze due the amount of Opportunities for Improvement (OFI’s) reported, but remember even award winners receive OFI’s! They are after all the real benefits of the process it is through these that an improvement plan can be developed. However, the number of OFI’s can be overwhelming and result in the OFI’s being sidelined and no action plan being put into place. In addition many organizations take offense at the OFI’s and regress as a result. The NHQA provide the opportunity for applicants to have a conference call with their Judges after they receive the feedback report. This is an excellent way to gain insights on the OFIs listed in the feedback report and to get suggestions on the priority of OFIs and clarification on each one. This can really provide the boost to starting addressing the feedback report.

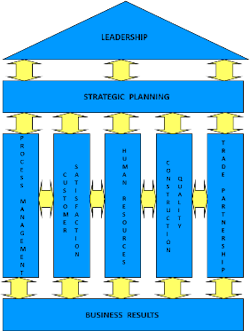

Whether or not a site visit is achieved teams need to be formed based on each criteria to distribute information from the feedback report when received following a similar format to the site visit debrief and announcement that was described earlier. These teams need to be made up of category experts and stakeholders from a range of departments or divisions to ensure that the knowledge and resources required are brought together. These teams need to work together on related issues so that work is not duplicated and that learning is maximized. Consensus within the teams and from the organization as a whole is crucial.

Everyone must be informed of the OFI action plans that are being developed and have input to the decisions being made. This ensures that everyone knows that this was not just about applying for an award, but about improving! Input can be via email responses, cross-functional meetings or retreats for example. Timelines, resources and milestones need to be scheduled to ensure that each of the identified OFI action plans are indeed addressed successfully. The implementation of these can follow the Plan, Do, Study, and Act process. The resulting improvements or best practices can then be shared across the organization. These can be shared through internal conferences and using shared folders or the organizations intranet to share processes, procedures and other tools and techniques that have been developed.

By using the methods outlined momentum can be sustained beyond the application submission and ensure that the OFI’s are addressed and the resulting impacts can be incorporated into the next application to continue to sustain and identify improvements on an ongoing basis driving continual improvement.

Attaining a site visit is in itself an achievement. It also ensures that a more accurate feedback report will be provided. The site visit provides opportunities and if well planned will be a valuable and not stressful experience. By focusing the organization on the feedback report and addressing the most critical and prioritized OFI’s rather than the application submission, the Quality Award process becomes a driver of continual improvement.

If your company is getting a second site visit the production of two reports can be a real advantage. These reports are provided to the Judge team either at the site visit opening meeting or in advance to the site visit team leader. The first report focuses on addressing how each of the OFIs listed in the last feedback report have been addressed with a reference to evidence (the evidence can be provided in a short appendix or detailed evidence file available during the site visit) it is a good use of time to focus the judges on exactly how their recommendations have been implemented.

The second report lists in bullet point criteria by sub criteria the changes that have occurred since the last visit, above and beyond the OFIs this may or may not include listing the expanded strengths. This would include projects that have been run as well as new tools and techniques that have been implemented.