If you think that Building Information Modeling (BIM) is just for high-end architectural firms, and not for builders like you, think again. BIM can now be readily integrated into your operations – from estimating/bidding to working with your component manufacturer – and BIM models offer accuracy and efficiency that will outweigh any expense or effort to implement BIM systems. Here’s why.

The buyer’s market in home building has led to a shift away from what-you-see-is-all-we-got production homes. Today, even production builders are ‘custom’ builders. To accommodate changes made by a buyer (even complicated structural changes), builders are adopting increasingly capable BIM 3D modeling, driven by CAD systems like, VertexBD, Autodesk’s ACA, Revit, or Chief Architect, and the growing list of modules from MiTek’s SAPPHIRE Suite.

As a house is optioned out, the home plan (and all purchasing) is now tied to lot-specific iterations of home plans. BIM systems reward users with super-accurate, super-detailed bills of material, which can be pulled right off the CAD file. Builders who have locked in good vendor relationships and pricing can quickly determine the custom home’s cost and markups on the fly. If you’re using the same BIM software as your supplier, or your supplier’s software can read your CAD files, collaboration, problem-solving and purchasing are super efficient.

Truss and wall-panel component manufacturing has really accompanied the advances in CAD systems, and a good truss shop enables the builder to build custom homes nearly at production speeds and costs by leveraging the right BIM software. Take Hiwassee Builder's Supply, which serves Tennessee builders through two locations in Athens and Knoxville, one of which fabricates trusses.

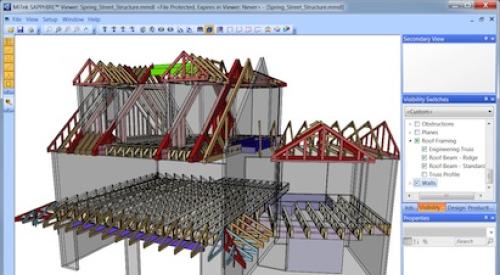

With a staff of 30, Hiwassee runs MiTek’s SAPPHIRE Suite to drive their operations and crank out thousands of components annually. Hiwassee’s Doug Beaty and his staff also implemented the use of free SAPPHIRE module called SAPPHIRE Viewer. Viewer shows the 3D model of the house framing, allowing Hiwassee to share its designs with builders, architects, and engineers; they can then view, comment on, and collaborate through these fully designed models. The same 3D models that the builders approve then also drive the shop’s component saws and automated assembly tables. After the components are manufactured, SAPPHIRE Viewer serves as an effective instructional tool for framing crews.

“We have SAPPHIRE™ Viewer on all our iPads,” Beaty explains, “and it’s really helpful for everyone, from our design teams all the way up to the guys on the jobsite. We have one builder who uses Viewer in his sales process, because he can pinch and zoom on the image on his iPad and show buyers exactly what the structure will look like,” Beaty explains.

“On today’s framing crews,” Beaty adds, “we are seeing lower skilled labor. Usually it’s one skilled worker who points and directs a crew. Now, you put an iPad in that guy’s hand with Viewer, and you get real clarity as to how everything should look. It takes any arguments out of the equation.”

To accommodate changes made by a buyer (even complicated structural changes), builders are adopting BIM 3D modeling CAD systems like VertexBD, Autodesk’s ACA, Revit, or Chief Architect, and the growing list of modules from MiTek’s SAPPHIRE Suite.

To accommodate changes made by a buyer (even complicated structural changes), builders are adopting BIM 3D modeling CAD systems like VertexBD, Autodesk’s ACA, Revit, or Chief Architect, and the growing list of modules from MiTek’s SAPPHIRE Suite.

Learn more at http://www.buildabilitynow.com/better-building/case-studies/hiwassee-structural-products/