9 Steps to Prevent Floor Squeaks

A beautiful, high-performance floor starts with what you can’t see—a stable floor frame and subfloor underneath. Simple installation mistakes can lead to squeaky floors or damaged finishes, along with the cost and hassle of associated callbacks.

How to Stop Squeaky Floors

Get it right the first time by following these installation best practices:

- Use the Right Materials. Choose dimensionally stable framing products. Wet or “green” lumber may lead to dimensional changes as the joists dry, resulting in nail pops, bumps in the finished floor, and squeaks. Use Trus Joist® TJI® joists or kiln-dried, performance-tested lumber, such as Weyerhaeuser Framer Series® lumber, which is more dimensionally stable than green lumber. Make sure joist size and spacing meet or exceed code-minimum requirements and that the panels are adequate for the applied loads, joist spacing, and floor system chosen. Inadequate joists or panels can result in excessive deflection, causing nail pops and squeaks.

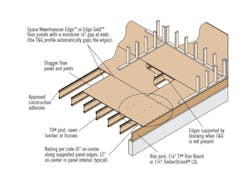

- Space Panels Properly. To avoid buckling, subfloor panels should be spaced with a 1/8-inch gap at all edges and ends to provide room for naturally occurring expansion. Tongue-and-groove edges on many premium floor panels, such as Weyerhaeuser’s Edge Gold® OSB panels, are designed to self-gap.

- Let the Subfloor Dry. Always store floor panels under cover. OSB exposed during construction must be allowed to dry (especially before installing sensitive finish materials such as hardwood flooring). Allow panels to acclimate before installing.

- Nail Panels Correctly. To avoid nail pops, pullouts, and shiners (nails that barely hit the joist), all of which can cause squeaks, use the correct nail size and spacing, and ensure the nails penetrate the floor joists and sink fully. Generally, nails (6d ring or screw shank, or 8d common) should be spaced 6 inches on center along supported panel edges and 12 inches on center on the panels’ interior supports, or as specified on the construction drawings. Many manufacturers print a fastener template directly on the panel face. For panels thicker than 1 inch, 10d nails should be used.

- Use Glue-Nailed Construction. A glued and nailed floor system is optimal for ensuring a flat, stable floor. Use a solvent-based glue that meets ASTM D3498 performance standards; in cases where latex subfloor glue is required, careful selection is necessary due to the wide range of performance between brands.

- Apply Glue Properly. Apply adhesive per manufacturer’s specifications. Be sure the joists are dry and free of dirt before applying. Many manufacturers recommend applying a continuous ¼-inch-diameter glue bead to framing members and using a serpentine pattern for supports that are 3½ inches or wider. Apply two beads of glue to panel joint locations; a 1/8-inch glue bead applied at the tongue-and-groove joints can further improve floor performance.

- Don’t Let Glue Dry. Apply only enough glue for one or two panels at a time, and completely fasten each panel before the glue is set. Check manufacturer specs for setting times, and keep in mind that warm weather can accelerate those times.

- Don’t Hammer Panel Edges. Using a sledgehammer to force a tongue-and-groove joint together tightly can crush the wood fibers, damaging both the panel hit as well as the one it is forced into. Further, it can close up the necessary gap on panel edges, leading to improper spacing issues mentioned above. If additional force is needed, always use a block of wood against the groove edge to minimize damage to the panel, and always allow a 1/8-inch gap between panels.

- Check Your Work. Prior to finished floor installation, walk the subfloor to check for squeaks, missing fasteners, improper nailing, etc.

Simple strategies such as these can help provide flooring systems that are sturdy, stable, and squeak-free.

Too late? If you’re dealing with squeaky floors caused by wet lumber, inadequate spacing, improper nailing, improper blocking, rubbing ductwork, or other issues, there are remedies. For strategies to diagnose and fix the problems, download Weyerhaeuser’s Technical Resource Sheet “Prevention and Repair of Floor System Squeaks.”