Note: This is part two in a two-part article about the Inside View advanced-framing demonstration home. To read part 1, click here.

For years, Beechen & Dill Homes has sought to remain on the leading edge of efficient building in its Chicago market. The company’s latest efforts can be seen in the Inside View demonstration home in Lockport, Illinois, where the builder teamed up with sponsors APA – The Engineered Wood Association and the U.S. Forest Service, Forest Products Laboratory to implement a number of advanced framing techniques that boost the 2,880-square-foot home’s energy efficiency and save homeowners money.

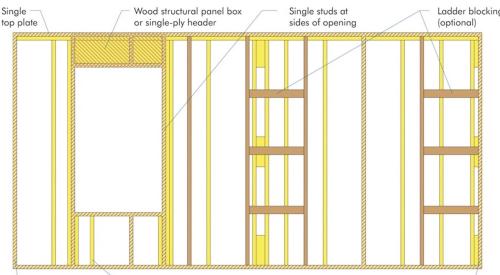

Many of these advanced building techniques can be seen in the walls, as outlined in our previous post. In addition, the house features a robust floor system that further demonstrates how advanced framing techniques can dramatically reduce excess materials and labor.

The floor system is framed with I-joists spaced 24 inches on center (o.c.), which allows builders to more easily accommodate ductwork in conditioned spaces, one of the most effective ways to eliminate energy inefficiencies in a home. Along with that, the spacing eliminates one-third of the joists, subsequently reducing labor, trim waste, adhesive, and fasteners by one-third.

One potential drawback to the wider joist spacing, however, is reduced subfloor stiffness. While the floor would still meet code requirements, it may feel bouncier underfoot when using code-minimum floor sheathing. To alleviate this risk, the Beechen & Dill team specified a more robust subfloor system. They upgraded from the typical 23/32 Performance Category (designates panel thickness) subfloor to a 7/8 Performance Category subfloor. The thicker panel is stiffer across the wider spacing, has improved nail retention, and is recognized by the National Wood Flooring Association for use under hardwood floors when joists are spaced 24 inches o.c. APA and the Tile Council of North America also recommend the system for use under ceramic tile.

The joists also are more robust: deeper (14 inches, versus 12 inches) and with a larger flange. The beefier joists not only allowed increased joist spacing, it also enabled the designer to eliminate 11 double joists that were part of the builder’s existing floor design.

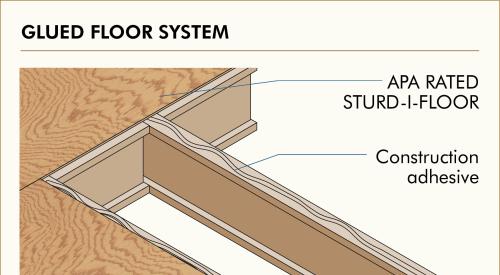

Finally, to ensure optimal performance of the floor system, the framing company, McNally Construction, employed a glue-nailed system using a number of installation best practices designed to prevent nail pops and floor squeaks. These strategies include:

- applying adhesive to the joists for just one or two panels at a time so that a tight bond can be achieved before the glue sets,

- applying a pencil-width of glue in a continuous line or serpentine pattern to each joist,

- gluing the OSB’s tongue-and-groove joints,

- fully nailing the panels while providing foot pressure to help get good glue “squeeze-out,”

- and using ring-shank nails.

“Using a glue-nailed system with thoughtful installation techniques gives you better performance and fewer problems,” notes framer Eamonn McNally.

Indeed, each of the techniques employed in the Inside View floor contributes to a higher-performing system, one that goes above code to accommodate energy-efficient building, reduce waste, and speed installation.

For more information on the Inside View project, visit http://www.apawood.org/insideview.