It’s a scenario that’s become all too common: A customer calls to complain about noisy floors underfoot or, worse, wearing floor boards because of nail pops below.

If not installed properly, floor systems can squeak, buckle, and even experience nail pops. Builders can prevent these problems with a few simple steps.

Step 1: Choose the correct materials

Use only dry lumber, which is more dimensionally stable than green lumber. Wet lumber can cause nail pops as it dries, which creates bumps under the finish flooring that lead to squeaks and to accelerated wear. Engineered wood is dried during production and, if properly installed, should not cause nail pop.

When selecting the floor panel, consider the applied load, joist spacing, finish flooring, and floor system (e.g., single floor or subflooring plus underlayment).

Step 2: Use proper panel spacing

From their initial mill-dry state, wood structural panels will expand as they reach their equilibrium moisture content. If they are installed without room to expand, panels may buckle. APA recommends leaving a 1/8-inch space at all sheathing and Sturd-I-Floor edge and end joints, including tongue-and-groove joints, unless otherwise directed by the product manufacturer (Figure 1).

To further minimize the potential for panel buckling, allow panels to acclimatize prior to installation. To do this, stand panels on edge for several days, allowing air circulation to all sides.

Step 3: Select the right adhesive

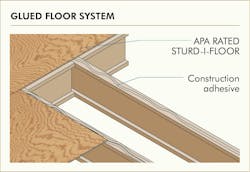

If using a glued floor system, select an adhesive that conforms to APA Performance Specification AFG-01 or ASTM D3498.

To prevent premature drying of the adhesive, spread enough glue to lay only one or two panels at a time. Wipe away water, dust, and debris before applying glue to ensure the panels will be firmly and permanently secured to the joists.

Apply glue (about a 1/4-inch-diameter bead) to framing members in a continuous line, or in a serpentine pattern in wide areas (Figure 2). Glue all tongue-and-groove joints by spreading glue in the groove. Avoid squeeze-out by applying a thinner line in grooves (about 1/8 inch) than on joists.

Be sure to nail each panel before the glue sets or skins over. Check the glue manufacturer’s recommendations for allowable time. And remember, warm weather accelerates glue setting.

Step 4: Nail panels correctly

The correct nail size and spacing for your job depends on your joist spacing and panel thickness, as well as the type of panel product you are using. Attachment schedules and fastener recommendations can be found at apawood.org/buildertips (select “Construct a Solid, Squeak Free Floor System”) or through your manufacturer.

For other structural wood panel application recommendations and typical panel trademarks, see APA’s “Engineered Wood Construction Guide,” Form E30.

This how-to article is part of the Builder Tips series of publications from APA-The Engineered Wood Association. To view more helpful strategies, visit apawood.org/buildertips.