Lean Construction Drawings: 4 Elements that should always be there and 1 that shouldn’t - Lean Tuesday with Todd Hallett

Plans, plans, plans, it’s sometimes difficult to know what they should include and what they shouldn’t. After spending the last two years with Scott Sedam and TrueNorth working with builders, suppliers, and trades all over the country we have developed a number of plan dos and don’ts regardless of geography, here are just a few:

Have:

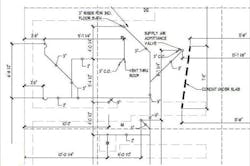

1. Rough Plumbing Dimensions – Dimension drains both horizontally and vertically on your foundation plans. The dimensions should tie to the outside of the foundation for a slab and to the inside of the wall for a basement. Do not rely on the plumber to interpolate the location of drains from the floor plans. Having these dimensions will result in a lot less hassle for your plumber and your project manager.

2. Diagonal Dimension on Foundation Plan – Provide a diagonal dimension on your foundation plan to allow the contractor to check square. This is typically to the outside corners of the plan. Verify the optimum placement with your contractor - it varies a bit also some may prefer locating the batter boards.

3. Flooring Breaks – Locating and labeling the flooring breaks will save time, money and phone calls in the field. It will also provide for consistent locations of flooring transitions so the floor can “look like the model” without an unnecessary reconnaissance trip to the model.

4. Header Locations and Sizes – Be specific. Show header sizing only at the openings that require them. I have seen enough wasted 2 x 10 headers if laid end to end they would, well not quite reach the moon, but I’m sure you get the point.

Have Not:

1. Window and Door Schedules: - If you currently have these on your plans the best case is that they are being ignored, worst case they are causing variances. I hear over and over again from suppliers that the schedules actually cause them grief as they try to tie the symbols back to the plans. Once they do figure out how to decode the hieroglyphics they generally find that the information is incorrect. The best practice I have come across is to use generic window and door sizing and show the sizing accurately on the plan and on the elevations. The rough opening sheet provided by the distributer can become part of the plan set. This way if your purchasing agent changes manufacturers, handing, sizing or anything else, the plans can be updated easily, efficiently and most important of all, accurately.