In last month’s column, I opened the discussion on where to go to find the home-building industry’s best innovators (see “The Innovators: Great Ideas From the Housing Giants”). I described the surprise expressed by some that after a quarter-century of working with home builders all over the continent, I have found the best innovators were rarely among the largest national builders in the major markets.

That honor goes instead to those highly entrepreneurial builders in the second half of Professional Builder’s top 100 list or even smaller, usually operating in secondary and tertiary markets, that through necessity are forced to innovate. This month we continue with more great strategies and tactics from home building’s exceptional innovators.

1. Early Input = Better Design + Lower Cost

The standard procedure for builders is to develop new plans and elevations, then throw them over the fence to purchasing, who then assembles a bid package and throws that over the fence to suppliers and trades. Is there a better way to lay out this house? Is there a more efficient design for the elevations? You never know until it is built, and then there is great reluctance to change drawings and specifications, especially if that affects the original permits and approvals.

The result is profit-robbing waste. South Jordan, Utah-based McArthur Homes decided to develop alternative floor plan concepts, then bring in key suppliers and trades up front to work out the most optimum design before moving forward. Working with their truss engineer, for example, they saved as much as $500 per house while actually improving the look from the original concept. Who can argue with a better-looking house for less money?

Most builders mistakenly believe this approach takes extra time, but for every hour you spend up front optimizing plans and getting them right, you’ll avoid large multiples of time and money downstream.

2. Success Built on a “Culture of Ownership”

In the process of building their company, it occurred to the management team at Atlantic Builders, Fredericksburg, Va., that if everyone understood how they make money and if each associate had a stake in the business through a companywide profit sharing plan, they’d make more money. Backed by a deep-seated belief that everyone’s opinion has value no matter what their position, they strongly encourage all to give their opinions on an issue or to lead an initiative.

The result at Atlantic is that most often the best ideas do not come from top management, rather from those on the front lines. Atlantic holds daily companywide huddles and weekly companywide meetings, where everybody shares their thoughts and ideas. Their Lean Team, for example — which is tackling their biggest initiative for 2012 — is intentionally made up of people from all areas of their company — except top management.

To support this culture, having the right people on the team is critical. Years ago, Atlantic hired more for skill sets than attitude. They concluded that knowledge is important, but an open mind, positive attitude, high energy level, and a strong work ethic are essential. This creates a team larger than the sum of its parts.

Tom Schoedel, Atlantic’s president, insists, “Skills can be learned, but attitude — not so much.” The culture of ownership, deep involvement of all associates, and exceptional attitudes has conspired to build a successful, thriving company.

3. Involve Suppliers and Trades to Boost Sales

The McKee Group, Springfield, Pa., needed a boost in incremental sales, so they asked their best trade partners to contribute an option at no cost — something they could offer without pain — with the hope of generating additional business from which they’d all benefit.

The suppliers and trades came through and McKee bundled a group of small options together and offered it to prospective home buyers for a limited time only. Called the Deluxe Package, it included: two extra recessed lights with a switch; an insulated garage door; one-piece crown molding in the master bedroom; R-49 attic insulation; roll-out trays in the cabinets; an upgraded kitchen faucet; custom paint color; a ceramic tile backsplash; and a 14 Seer AC unit.

It was a great success for all, creating a sense of urgency with buyers. For giving up an easily absorbed upgrade, the suppliers and trades got more work. The sales staff was particularly pleased with how this package helped convert the fence-sitters into contracts.

4. Open-Book Management

Gallatin, Tenn.-based Goodall Homes has built their operating culture around open-book management. They gather their entire team — literally everyone — once each week for an hour to review key financial and operational reports, along with other relevant information that helps the team identify and understand successes and shortfalls. By doing this, every individual on the team knows how they impact the bottom line, and required adjustments are made quickly and effectively.

As part of this process, Goodall management created “mini-games” for all the departments in the company, whereby each department identifies an issue they can control that will significantly affect the overall success of the company. Each team then sets monthly and quarterly goals with a scoring system. At the end of the quarter, the team with the highest score gets a special reward, and if the company as a whole meets a predetermined point goal, they take a day off for a company trip or outing, such as a sporting event, amusement park, or community tour. Through their mini-games, Goodall has lowered variances and overheads and improved gross margins.

5. Visual Scopes — A Picture is Worth 1,000 Words

Traditionally, builders draft scopes of work as part of the standard vendor contract package more for liability protection than as a guide on how to build a house right. If you assign all the responsibility to the trades you are protected, right? These documents are signed by the trade contractor and filed away with insurance forms, never again to see the light of day.

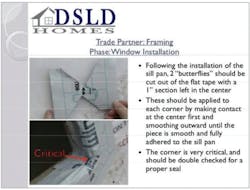

DSLD Homes’ markedly different approach is to create a truly functional scope of work as a living, working document that clearly conveys performance requirements for each trade partner. A trade should not have to guess what the superintendent might check, nor should the superintendent be forced to hope the trade completes the job to the inspector’s standards, without being fully informed about the code requirements.

ABOVE: To avoid construction issues, DSLD Homes provides its trades, superintendents, and inspectors with a concise pictorial depiction of their construction standards for every major trade. Shown are window installation instructions.

Trades and superintendents alike must know the “answers to the test” before they show up to the jobsite. To bridge the gap between trades, superintendents, and inspectors, Denham Springs, La.-based DSLD provides a concise pictorial depiction of their construction standards for every major trade. These also help solve language barriers that are increasingly common at building sites around the country. The “field guides” are revised and published as often as necessary to keep up with product and process changes, and updates are distributed electronically to every field employee and trade partner.

DSLD demonstrates this system to the municipalities prior to construction, as opposed to employing the old “build it our way and hope for the best” approach that is normally attempted by builders in new locations. This strategy has improved scalability and reduced re-work, which helps reduce operating costs and maintain profitability.

6. Hire Suppliers and Trades By Value — Not By Price

As part of their sophisticated supply-chain management system, Keystone Custom Homes, Lancaster, Pa., employs a results-oriented, data-driven supplier and trade management tool based on the principles of transparency, equity, value, and objectivity. It measures each trade’s performance in six areas: key relationships, cost, service, capacity, quality, and safety. These combine to create a total value scorecard by which all vendor decisions are based. This drives continuous improvement across all six factors in a competitive environment while never being “just about price.”

The system has been well received by Keystone Custom’s suppliers and trades, who see it as inherently fair and mutually beneficial. The results are strengthened supplier/trade loyalty, quantifiable increases in productivity, and reduced hard cost.

7. Home Building As Stewardship

When you walk into Betenbough’s Lubbock, Texas, headquarters, there is no question that you have entered a unique environment. Your first thought is, “Wouldn’t it be great to come to work here every day?” You are surrounded by remarkable architecture of brick, glass, and steel, an open environment, and beautiful artwork — all in a theme of an old train station and so inviting that it takes your breath away. There is nothing ostentatious about the place; it is just, well, totally cool. The beautiful foliage, ponds, and fountains in the back belie the fact that just beyond the trees lays a Wal-Mart parking lot.

ABOVE: Stunning architecture and beautiful artwork make Betenbough’s Lubbock, Texas, headquarters a great place to work. But its company culture and people are the true gems, driven by a profound sense of stewardship and service to a higher cause.

Yet for all of this physical beauty, it pales in comparison to the spiritual beauty you encounter while getting to know the Betenbough people. Each one greets you warmly and you soon realize that these people are not merely gracious and polite; they treat you like family, like they really care — because they do. As you walk around the office and tour the jobsites, Betenbough associates are just as likely to tell you about their most recent mission trip — often funded by the company — as they are about their new plans, continued growth, or healthy profits. In my long career I have never encountered a group of people so thoroughly happy to be doing productive work with a great company, and they all see their work as service to a higher cause.

How have Ron and Rick Betenbough created such an exceptional culture in a 450-annual unit builder? I have studied them and here is my simple conclusion: More than any other home builder I have met, Ron and Rick instill their company, top to bottom, with a profound sense of stewardship. They view every single thing they have received as a gift they are entrusted with — temporarily — and their mission on Earth is to care for these gifts, grow them, leave them greater than they found them, and help as many people as they possibly can.

After my most recent visit to Lubbock, I left with an overwhelming thought: If our industry — perhaps any industry — were to adopt the sense of stewardship embodied in the Betenbough culture, everything would change for the better. Most of our problems would melt away, and those that remained we’d tackle with grace, dignity, and aplomb.

Another month has passed since the first part of this two-part series was published, and after checking in with these builders, I’m happy to report that their sales volumes continue to climb in 2012 well above the national average. The specific strategies described here do not account for all of their successes, but these are the kinds of things that truly innovative companies do.

No doubt, there are at least a few ideas among the 15 in the series that you can adopt directly, but beware the admonishment from the late quality and management guru Dr. W. Edwards Deming: “You cannot copy. You must understand why.”

So use your team to think these innovations through in the context of your own strengths and local market. Engage in a deep and detailed conversation and there is no doubt you’ll arrive at a list of your own that will make a difference in 2012 and beyond. Adopt the culture of innovation found in these builders and there is no question that improved sales and profit will result.

About the Author

Scott Sedam

Scott Sedam is president of TrueNorth Development, a consulting and training firm that works with builders to improve products, process, and profits. A senior contributing editor to Pro Builder, Scott writes about all aspects of the home building business and won the 2015 Jesse H. Neal Award, business journalism's most prestigious prize, for his commentary in Pro Builder. Scott invites you to join TrueNorth's Lean Building Group on LinkedIn and welcomes your feedback at [email protected] or 248.446.1275.