Forced-air distribution systems (duct systems) typically are installed out of sight for aesthetic reasons, most often in attics and crawlspaces. But any air leaks in the duct system in unconditioned space mean that not only is energy being lost but that the home’s equipment durability and indoor air quality are also affected. For energy savings and comfort, the U.S. Department of Energy (DOE) Zero Energy Ready Home Program requires that all ducts be installed inside conditioned space.

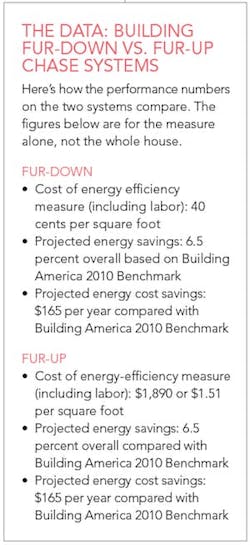

One solution for limiting loss to unconditioned space is sealing the area—such as the attic or crawlspace—where the ducts are installed, or by building an interior cavity or chase above the ceiling plane (raised ceiling or fur-up chase) or below the ceiling plane (dropped ceiling or fur-down) for the duct system. Both strategies are viable and offer cost savings compared with a foam-sealed attic solution.

Recently, the DOE Building America program conducted research, development, and demonstration (RD&D) projects to develop best practices associated with these innovative construction techniques. Building America is the foundational RD&D program that supports the advancement of residential initiatives, including the DOE Zero Energy Ready Home program.

RELATED

- Getting HVAC Right: Consider These Tips When Sizing and Specifying

- Next-Gen HVAC and Indoor Air Quality

- Durable and Efficient HVAC Products

Building a Fur-Down Chase

To demonstrate the fur-down chase method, the Building America Partnership for Improved Residential Construction (BA-PIRC) partnered with Tommy Williams Homes to test an inexpensive and effective method of building a fur-down chase. An interior duct system is built inside a home’s thermal and air barrier. A dropped ceiling or fur-down chase places the duct system below the ceiling plane of the house in a framed chase. Sealing the top plane of the chase from the attic above is the most difficult and important part of this procedure. If the job is badly done, the chase will leak air toward the attic, defeating the main purpose, which is to eliminate duct leaks to the outside. By designing the chase’s path to avoid intersecting load-bearing walls, sealing of the chase’s top plane, or ceiling, is fairly easy. Non-load-bearing walls need to be built with a gap of ¾ inches between the top plate of the wall and the bottom chord of the attic trusses. This space allows the chase’s ceiling drywall to extend beyond the borders of the chase.

Building a Fur-Up Chase

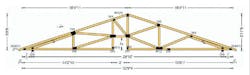

This is also known as a raised ceiling chase. To demonstrate the fur-up chase method, BA-PIRC partnered with builder S.E. Volusia County Habitat for Humanity (SEVHFH). SEVHFH was interested in constructing a home to DOE’s Zero Energy Ready Home standards. SEVHFH regularly partners with BA-PIRC and routinely builds to Energy Star V3.1. The only design modification needed to comply with the Zero Energy Ready Home criteria was the interior duct requirement. Unwilling to incur the added costs of a foam roof deck or wall heights that exceed 8 feet to accommodate a fur-down chase, SEVHFH opted to build and test a fur-up or raised-ceiling chase.

Fur-up chases require different attention to detail than a standard build. Typically, a home’s roof trusses need to be redesigned and duct size in lateral run-outs is constrained to the width of the trusses, usually 21 inches (2 feet on center). The order in which trades are required changes, and the trades can affect the success or failure of a chase-based interior duct system. Also, air sealing and insulating the resulting chase where it rises above the attic floor can pose significant challenges.

Note that you can access complete information on how to implement the two strategies highlighted in this article in the Solution Center.