They’re cost-effective, simple, and safe: “combi” systems that combine HVAC and water heating are starting to gain traction in U.S. homes.

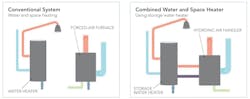

For several years, NorthernSTAR, one of the U.S. Department of Energy’s Building America research teams, has been testing systems that replace natural gas forced-air distribution system furnaces and tank-type water heaters. These new systems consist of a water heater or boiler heating plant, using a hydronic air handling unit (AHU) along with a water coil and a water pump to circulate hot water between the boiler and the coil for heating, and through a separate circuit for domestic hot water (DHW).

TERMS TO KNOW

Set-point reset: The supply water set-point temperature is reset by outdoor air temperature control. This method has been widely used for commercial and residential boilers.

Flow-rate modulation: Air- and water-flow rates adjust to an optimized output rate that varies based on demand.

DHW priority: This control prevents any space heating when the domestic hot water system is active. For example, if hot water is being used for a shower when the house thermostat calls for heat, a flow-control valve in the combi system prevents (or, for some systems, limits) the space-heating flow rate system until DHW flow is no longer sensed.

Research shows that using condensing water heaters or boilers with hydronic air handling units can provide both space- and water-heating efficiencies of 90 percent or higher. This provides significant gains, especially for hot water, which normally is limited to 67 percent efficiency for typical tank- type gas water heaters. Combi systems are feasible for typical houses in most climate regions, although they may not be well-suited to very large homes with poorly insulated, leaky envelopes in very cold climates.

Condensing combi systems are still relatively new and complex, and they often require on-site engineering and optimization to achieve desired performance. One of the takeaways from previous research work was the need for advanced controls to further enhance system efficiency. The energy efficiency of combi systems largely depends on the water temperature returning to the heating plant from the air handler and on burner cycling characteristics. In general, lower return temperatures and longer cycles produce higher system efficiency. However, air handlers have a constant airflow and water circulation flow rate for the heating mode. To achieve the best performance, these flow rates must be adjusted to meet the house design heating load and to minimize the return water temperature. Such advanced controls are more precise, more tailored to the individual home, and allow for a range of heating capacities for improved efficiency.

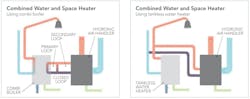

Control strategies are less effective for boiler-based combi systems (left) and for those that rely on tankless water heaters (right).

Combi Systems: Encouraging Results

The tests demonstrate that advanced controls can significantly benefit first-generation combi systems. The laboratory tests and daily load/performance models showed that the set-point temperature reset control produced a 2.1 percent to 4.3 percent (20 to 40 therms per year) savings for storage and hybrid water heater combi systems operated in moderate-load homes. The full modulation control showed additional savings over set-point control (in high-load homes, the savings nearly doubled: 4 percent to 5 percent over the no-control case).

BEYOND ENERGY EFFICIENCY

In addition to their outstanding energy efficiency, combi systems offer several other benefits over installing separate systems for space and water heating.

Cost-effectiveness: Installing a high-efficiency combi system may cost less than installing a similarly efficient separate furnace and water heater.

Simplicity: The system replaces a separate furnace and water heater with a single boiler or water heater. This reduces the number of gas lines and exhaust vents from two to one and helps minimize the equipment footprint.

Safety: A single high-efficiency burner has combustion safety and venting benefits. The high-efficiency combi heating plants have power-vent or sealed combustion burners that eliminate combustion spillage concerns for tight houses.

The field testing and analysis showed that a reduction in set-point temperature from 140° F to 130° F resulted in an average reduction in return water temperature of 4° F. These homes experienced savings of 1 percent to 4 percent (an average of 2.5 percent) on their annual energy bills with the reduced set point.

Although the control strategies provided energy cost savings, the biggest benefit may be a simpler commissioning process that more reliably results in high-efficiency operation. Previous NorthernSTAR research has shown that improper commissioning or inaccurate characterization of the design heating load can reduce combi-system efficiency from approximately 90 percent to 75 percent. Implementing the set-point reset or fully modulating control strategies would allow the system to automatically reduce capacity to the most efficient operating point and still meet the load.

This PDF provides additional information.