The U.S. Department of Energy (DOE) has set aggressive goals of 30 to 50 percent whole-home energy savings for U.S. homes. A good place to start is HVAC.

System ducts located in unconditioned spaces, such as vented attics and crawlspaces, represent significant losses. A primary strategy to reduce these losses includes locating ductwork within the thermal envelope. This is most often achieved by installing HVAC equipment and ducts in a sealed and insulated basement or crawlspace, or by locating the HVAC equipment in conditioned space such as a mechanical closet and locating the ducts in conditioned spaces such as an unvented attic insulated at the slope, raised ceiling spaces, dropped ceiling spaces, or interstitial space in the flooring.

These insulated ducts are on joists with centrally located supply registers showing, but these are open-web floor joists—not attic roof trusses (Photo: Courtesy Building America)

The trouble is, such solutions aren’t always practical or possible. Slab-on-grade homes don’t have a basement available for HVAC equipment and ducts. Dropped ceilings, chases, and soffits may not be compatible with preferred design solutions. Unvented attic assemblies require additional expertise, materials, and costs that are often not acceptable to mainstream builders. Two practices—buried ducts and compact duct design—can reduce energy loss while using the normal vented attic duct location.

Buried Ducts

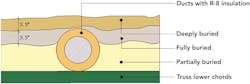

Buried ducts are insulated ducts that run in the attic on top of ceiling framing where they can be fully covered or buried with attic insulation.

A buried, unfoamed duct installation (llustration: Courtesy Steven Winter Associates)

A problem with buried ducts is condensation on the outside of the duct insulation, especially in hot, humid climates during the cooling season. Buried ducts must be well sealed and insulated: Condensation is apt to happen when the air conditioner cycles on and cold, conditioned air leaks onto the condensing surface through tears and seams. Encapsulating the attic ducts in closed-cell spray foam insulation will help overcome condensation, but it can disrupt the normal work sequence and requires a specially trained crew and safety procedures, plus additional materials.

Compact Ducts

Compact duct design refers to duct layouts that minimize overall duct length and area, reducing energy loss caused by conduction, leakage, and pressure drop. Compact ducts are possible in high-performance homes because supply registers no longer need to extend to outside walls to avoid condensation and offset cold surface temperatures of inefficient windows.

Compact duct design can significantly reduce energy loss from ducts that can’t be located in conditioned spaces. It reduces duct pressure losses, improves airflow performance, and lowers fan power. The reduced duct area in the attic minimizes conduction and leakage energy losses to the outdoors and can also translate into lower installed cost.

The most important considerations for compact duct layout are location, performance, and noise control. Here are some general guidelines for designing a compact duct system.

• Locate the air handling unit centrally, to help reduce total duct length and area.

• The return offers the best opportunity to reduce total duct length and area. Ideally, locate a single, central return trunk near the air handling unit that serves one return grille per living level.

• Locate supply registers to reduce supply branch duct length, while still providing acceptable air mixing and preventing unacceptable noise and drafts.

• In rooms where a ceiling supply register is not available with sufficient throw within acceptable noise limits, a register can be located in the middle of the ceiling.

• For supply ducts in vented attics, install ducts away from the roof deck. This reduces duct area and energy losses. Install ducts that will be buried close to the ceiling plane, ideally before installing a sprinkler, plumbing, and electric rough-ins. Install ducts that will not be buried just above the attic insulation.

• Ducts should be sized and registers and grilles should be selected in accordance with manufacturer performance data and ACCA Manual D, “Table A1-1: Air Velocity for Noise Control” and “Appendix 13: Noise.” Where the return grille is near the furnace, pay particular attention to air velocity limits, turbulence due to duct geometry, and attenuation of blower noise and rumbling sounds.

A Compact Buried Hybrid

Our research team tried out a technique that doesn’t require encapsulating ducts. Instead, it combines compact duct design with a buried duct strategy. Installed in a slab-on-grade one-story house in South Carolina for one month in summer, the system had no problems with condensation and delivered cooler air ducts than unburied ones. Of note is that R-8 insulation—long thought to be inadequate for preventing condensation in buried duct systems in hot, humid climates—showed no condensation problems here.

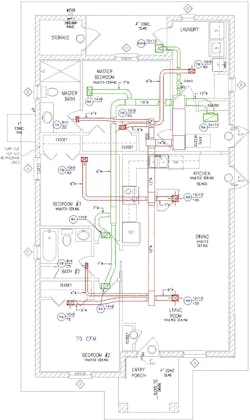

This duct layout shows compact duct design with interior throws (supply registers along inside walls, not exterior walls). (Illustration: Courtesy Calcs Plus)

Simulations predicted that the system will yield an annual energy savings of 21 percent, compared with a conventional vented attic duct system. The compact buried duct system is a balanced solution that saves energy and uses a standard duct layout approach that doesn’t require excessive or custom design changes. This strategy is potentially scalable for many home designs in most climates and markets, though you will still need to set the HVAC equipment in a conditioned space.

Compact Buried Ducts in Cold Climates

Supported by the DOE’s Building America program, Home Innovation Research Labs partnered with K. Hovnanian Homes to develop and show a new buried-duct design that is durable, energy efficient, and cost-effective in a hot, humid climate. The goal was to design and develop guidelines for a system that uses common materials, doesn’t rely on encapsulation, and won’t disrupt workflow.

Project Information

• Construction: New home

• Type: Single-family

• Location: Lady’s Island, S.C.

• Size: 2,222 feet

• Price range: $300,000

• Date completed: August 2015

• Climate zone: Hot-humid (IECC 3A)

Performance Data

• HERS index score: N/A

• Projected annual energy cost savings: $281

• Incremental cost of energy-efficiency measures: $732

• Incremental annual mortgage fee: $42

• Annual cash flow: $239

Key Features of the Compact Buried Duct System

• Heat-pump air handling unit installed in mechanical closet (in conditioned space)

• Single central-return duct located near the air handling unit

• Bedroom transfer grilles provide the return air path to the central return

• Supply-air registers primarily located in the ceiling near interior walls

• Ducts sealed using mastic

• R-38 insulation in vented attic, plus R-30 insulation mounded over the buried ducts (R-8 duct insulation)

Full research results from this project can be found here, and practical guidelines for designing and constructing compact buried duct systems can be found in the “HVAC/Ducts” section of the Building America Solution Center.