Vinyl siding was introduced to the housing market in the 1950s, but it had very little market penetration. Like many new building products, early inconsistencies and quality issues made it stumble out of the gate. Back then, the U.S. Census Bureau didn’t even track metrics for how many new homes were using the product.

But vinyl siding experienced a transformation starting in the 1970s, changes that affected the product’s impact resistance, durability, and color options. Fast-forward 20 years to 1994 and vinyl was the No. 1 cladding material on new homes.

Today vinyl has competition—strong competition. After peaking at a 40% share of the siding market in the new-home sector, vinyl now accounts for about 27% (though the material dominates the new-home market in the Northeast and Midwest).

Builders that want siding options have an extremely wide variety from which to choose, including various types of composites, cellular PVC, bark, a range of heat-treated wood options, fiber cement, steel, aluminum, polymers, fiber-reinforced concrete, wood composites, and more. And manufacturers are promising easy installation, low maintenance, and protection from extreme weather.

The new (material) kids on the block may be offering much, but the thing that’s hard to beat with vinyl siding is its cost, which starts at around $1 per square foot. Any material hoping to dethrone the top dog had better bring a better value proposition ... or offer bullet-proof features and a host of other benefits.

RELATED

- Siding Options: How to Choose ... Vinyl or Other Exterior Materials?

- Curb Appeal—Builders and Architects Shed Light on Buyer Preferences

- Construction Details: Trouble-Free Fiber-Cement Siding

8 New Siding Products for Curb Appeal

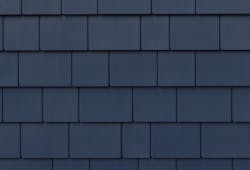

Painted-Wood–Look Composite Siding

Offering a 5-inch exposure and a subtle wood texture, Tando’s TandoShake Cape Cod Perfection polypropylene composite siding (also see lead image, above) features crisp, square edges and the look of painted wood. The manufacturer says Cape Cod Perfection is easy to install and it comes in a variety of solid colors, including Classic White, Ashwood Gray, Slate Gray, Wheat, and Mariner Blue (shown).

Press-and-Click Wood Siding

Made from heat-treated ash, the PaCS (Press and Click Strips) cladding system from Thermory USA allows for easy “press and click” installation. The wood is sourced from managed U.S. forests and is engineered to reduce warping and decay. It’s available in four standard profiles or custom options.

Engineered Composite Shingles

Grayne engineered composite shingles from Foundry, a Boral company, offer the look of real white cedar and red cedar. The red cedar-look shingle comes in a 7 1/2-inch profile, and the white cedar-look shingle comes in a 5-inch profile. The shingles are moisture- and rot-resistant and are available in a variety of colors, including a paintable version.

Wood-Look Polymer Siding

CertainTeed’s Cedar Impressions Triple 5 Sawmill shingles emulate the natural look of cedar but are made of an injection-molded polymer. Each 0.090-inch-thick panel projects 1 inch from the wall and various colors are available.

Composite Shake Siding

DaVinci Roofscapes’ new line of Hand-Split Shake Siding mimics the look of cedar but won’t cup or split the manufacturer says. Made of virgin resins, UV and thermal stabilizers, plus a specialized fire retardant, the siding is resistant to impact, fire, mold, algae, salt air, and high winds and comes in eight colors. Tiles measure 18 inches tall, 5/8 inch thick, and 8 or 10 inches wide.

Modified Wood Siding

Kebony’s engineered Character 90-degree Shiplap is made from FSC-certified Scots pine, which is treated with a bio-based liquid. The permanently altered boards maintain the look of real wood with greater durability and less maintenance than traditional softwoods, the company says.

Fiber-Cement Siding

James Hardie Building Products’ Artisan Shingle mimics the look of traditional cedar shingles while offering the durability of a fiber-cement composite material. Shingles are available primed or with the brand’s ColorPlus Technology in a two-tone look.

Poly-Ash Siding

Boral’s TrueExterior mimics the look of channel siding but is made from a blend of polymers and fly ash from coal treatment plants so that it resists rotting, termites, and cracking, and remains stable during temperature and moisture changes. TrueExterior requires no end-sealing and is easy to cut, drill, and saw, the company says.