Heat pumps are all the rage right now, and for good reason: highly efficient units may use two to three times less energy than conventional furnaces or air conditioners do. But while the efficiency of heating, ventilation, and air conditioning (HVAC) equipment has improved across the board, improper installation or commissioning can result in HVAC system faults that compromise HVAC performance and reduce energy efficiency. In addition, HVAC systems are often oversized, leading to more frequent cycling and higher energy bills. HVAC faults also sometimes arise after installation, such as a line getting a kink in it, or there being too much refrigerant, or not enough.

Whatever the case, these HVAC “faults” usually go undetected, even though they can severely compromise the energy efficiency of a home’s HVAC system.

HVAC System Fault Detection: Why It Matters

“For decades, our cars have been telling us when faults occur,” Eric Werling, program director of the U.S. Department of Energy's (DOE) Building America program, points out. “Shouldn’t we have fault-detection technology in our home HVAC systems, too?” Recognizing that, Building America is working on research into fault detection in HVAC systems now, Werling says.

Too often, installers don’t take the time to ensure HVAC systems are working optimally, and homeowners don’t receive feedback that lets them know there’s a problem with their HVAC system, says Tom Downey, chief technical officer at Proctor Engineering Group, an energy-efficiency engineering company. “Many installers just confirm that [the HVAC system] is blowing cold air and it’s quiet,” Downey says. Homeowners may not even be aware that they’re paying more than they should for heating and cooling. “They see a reduction in utility costs because they’ve installed a more efficient system,” he says, “but it’s not the reduction it should have been.”

However, there’s another reason why homeowners should care about improperly commissioned HVAC equipment, says professor David Yuill in the Department of Architectural Engineering & Construction at the University of Nebraska–Lincoln. “The most serious thing about HVAC faults, from a homeowner’s perspective, is that they reduce the life of equipment,” he says. When the compressor runs hot, for example, the oil that protects and lubricates its moving parts doesn’t work as well, causing those parts to wear prematurely.

RELATED

- DOE Announces New Efficiency Standards for AC Units and Heat Pumps

- Durable and Efficient HVAC Products

- A Right-Sized, Integrated HVAC System for Indoor Comfort and Health

- Getting Older Homes Up to Snuff for Energy Efficiency

Yuill says most faults go undetected and that we don’t fully understand which faults are most likely to occur. His doctoral thesis, which focused on HVAC fault detection and diagnostics, showed that many existing tools are ineffective.

There’s a lot at stake: According to the Energy Information Administration, space heating and cooling accounts for more than 35% of all residential primary energy consumption. And previous Building America lab experiments show that faults can increase space conditioning energy use by up to 30% over the lifetime of the system.

Building America is supporting several research projects to investigate the prevalence and severity of HVAC installation faults and to test the efficacy of diagnostic tools. This research is critical for addressing knowledge gaps and should help the DOE and the HVAC industry better direct resources.

How to Detect Problems in HVAC Systems

In 2019, Building America selected two teams to investigate the prevalence and detection of HVAC faults across several climate zones. The goal, according to Yuill, was to find out exactly how big of a problem HVAC faults are, so Building America could determine the resources it should put toward fault detection, specifically, “Do we put those resources toward increasing the energy efficiency of equipment, or into making systems that are robust against faults, or into programs that address faults?” Yuill asks. “Until we have the results from these projects, we’re just guessing.”

A team from the University of Nebraska–Lincoln, headed by Yuill, is focused on developing reliable, noninvasive field methods for finding HVAC faults.

“We searched the world for methods, shortlisted them, and tried them out in the lab while we imposed faults on the units,” Yuill says. “What we found is that some faults really don’t have effective methods for detecting them.”

During those months when COVID prevented Yuill’s team from visiting homes in the field, they focused on refining existing methods and developing new ones.

His team also developed and patented an HVAC fault monitor, called the NUBox, which detects issues such as leaking refrigerant and tracks the power use of air conditioning units, which can help to determine whether units are sized correctly. Because these monitors were so expensive, Yuill and his students built them in his lab; over time, they have been able to refine the monitors and cut the cost by half.

Last summer, the team began field testing in more than 120 houses in Omaha, Neb., and San Antonio. So far, testing has revealed quite a few HVAC systems with significant faults. For example, about 40% of systems had a deviation in refrigerant charge.

Field tests will continue through 2024, expanding to other regions across the U.S., and the team has also deployed some prototype NUBox monitors to collect long-term data. What About HVAC Faults in Cooling-Dominated Climates?

Research Into HVAC Faults in Cooling-Dominated Climates

Meanwhile, researchers at the Florida Solar Energy Center (FSEC) have teamed up with Proctor Engineering Group on field and lab studies to better understand the prevalence and severity of HVAC faults in cooling-dominated climates.

“Refrigerant-type installation faults are common and a big issue,” says Eric Martin, program director in the Buildings Research Division at FSEC.

Proctor Engineering Group is coordinating the field study and has recruited 85 homes across the Southwest and Southeast that received a new air conditioner or heat pump within the last 12 months. The sample includes a control group of homes that had their central cooling systems replaced through a utility quality assurance program.

Space heating and cooling accounts for more than 35% of all residential primary energy consumption, according to the Energy Information Administration. And previous Building America lab experiments show that faults can increase space conditioning energy use by up to 30% over the lifetime of the system.

The researchers are performing a suite of tests on these systems, including measuring refrigerant charge, static pressure, duct leakage, blower fan airflow, and condenser and blower fan watt draw. “We’re assessing the quality of installation,” Downey says, “and looking at installation faults for the equipment itself—improper airflow assignment, for example, but also duct leakage—along with design-type faults, such as improper sizing.” Proctor’s team began collecting field data last year and expects to finish this summer.

FSEC is coordinating the lab studies and is measuring the performance of heat pumps installed in two lab homes on the FSEC campus. The homes are built side-by-side. In one, the installation is as close to perfect as possible; in the other home, the team is imposing various combinations of refrigerant charge and duct leakage faults in an effort to quantify the impact of various faults and the resulting increase in energy cost. The team is collecting short-term data over a range of outdoor temperatures for each fault to extrapolate the seasonal impact, Martin says. This data will add to the body of knowledge and help researchers understand how much extra energy use is at stake.

The data from all of these projects will be synthesized with Building America’s larger data set on HVAC faults, which dates back to the 1990s. It will also help guide installation practices and further research.

Six Common HVAC Faults

Two Automated Fault-Detection and Diagnostics Tools for HVAC Systems

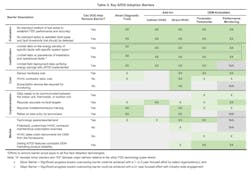

Another Building America project, which is headed by Southface Institute, a sustainable building nonprofit, is investigating the efficacy of two newer automated fault-detection and diagnostic (AFDD) tools: MeasureQuick and Sensi Predict smart HVAC.

MeasureQuick

This free app is designed to work with Bluetooth-enabled contractor HVAC apps and tools, such as probes that measure temperature and line pressure. The app, which can be used with new or existing systems, can live-stream detailed snapshots of system performance and help technicians diagnose existing faults and confirm proper installation.

“MeasureQuick helps contractors fine-tune out-of-the-box factory settings like fan speed so the unit is running at peak performance,” says Southface Institute technical principal Bryant Hains.

Sensi Predict Smart HVAC

Sensi Predict is an AFDD tool developed by Emerson Electric that’s designed to monitor systems that are already up and running. Sensors take continuous measurements on metrics such as supply and return air temperature, condenser voltage and current, and liquid/suction line temperature. Contractors access the data over Wi-Fi.

“Sensi Predict functions like a check-engine light for HVAC,” Hains says. It provides the homeowner with high-level alerts, while the HVAC contractor receives more detailed information about the suspected problem.

The Southface team has recruited HVAC contractors all over the country to use these tools and will analyze the data gathered to quantify how much energy they are saving. The team is analyzing a year’s worth of data, evaluating new installations and comparing performance before and after tune-ups.

RELATED

“We are finding consistent demonstrable performance improvement when the tools are used correctly, but we’re also realizing the importance of and need for proper technician training with these new technologies to realize their full potential,” says Hugh Magande, technical principal at Southface Institute.

Another aspect of the project will use interviews and surveys with contractors to learn if the tools are helping HVAC technicians be more productive and efficient, and how their homeowner customers are responding to the tools.

Tools such as MeasureQuick and Sensi Predict represent a new business model and have the potential to bring the HVAC industry into the 21st century, Werling says. “Rather than a trade service agreement, where the tech comes to the house every season to change filters and tune the system, the tech only comes if Sensi Predict sends an alert that something isn’t right.”

Better Tools for HVAC Fault Detection

In 2022, three national laboratories co-published a study investigating technological and market barriers to HVAC fault detection.

HVAC fault detection and diagnostic tools have been on the market for some time, but they’re not widely deployed, says Jon Winkler, senior engineer at the National Renewable Energy Laboratory (NREL) and lead author of the study. For one, there’s no standardized set of tests or metrics for evaluating how good AFDD tools are at detecting HVAC faults. “It’s hard for utilities to incentivize their use when there’s no way to say how effective [the tools] are at identifying faults,” Winkler says. “No one really knows how much energy they’re saving.”

Cost is another barrier. Often, AFDD technology for HVAC systems is an add-on cost, and most homeowners aren’t willing to pay for it for existing HVAC systems.

Finally, though one benefit of AFDD tools for HVAC is that contractors don’t have to visit homes as often, HVAC technicians don’t necessarily see that as an advantage. “They like to show up at the house twice a year and have that relationship with homeowners,” Winkler points out.

“We are finding consistent demonstrable performance improvement when the tools are used correctly, but we’re also realizing the importance of and need for proper technician training with these new technologies to realize their full potential.” —Hugh Magande, technical principal, Southface Institute

Despite the barriers, shortcomings, and information gaps, Winkler believes smart diagnostic tools likely do improve HVAC installation, and he supports efforts to deploy them more widely. He’s also working on an algorithm that uses a home’s thermostat to help detect faults; a solution that could help bring affordable fault detection for HVAC to more customers.

Downey says AFDD tools are useful to a point, assuming they’ve been validated and they complement, not replace, HVAC technician knowledge. In his view, if the goal is truly better HVAC performance—and, as a consequence, energy savings—contractors must receive better training. “What we’re finding in our programs is that it’s important for technicians to have that feedback mechanism to make sure stuff is done correctly,” Downey says. He cites the quality installation programs of utilities, which give contractors feedback; in addition, the utility physically inspects and tests HVAC units to make sure they were installed and commissioned correctly. Unfortunately, such programs capture just a small percentage of installations.

Barriers to Adoption of Automated Fault-Detection and Diagnostic Tools

HVAC Tools, Training, and Tech Support to Boost HVAC Performance

In 1997, Proctor Engineering Group developed a system called CheckMe!, which combines diagnostics, verification, and quality assurance with an HVAC technician training program. “We recruit contractors and train them with extensive classroom and field training to make sure they understand how to install systems correctly,” Downey says. “They go out and install the system, collect data on performance, and report the data to our call center. We confirm that the system is operating the way it’s supposed to.” Technicians receive immediate feedback from a CheckMe! operator, enabling them to correct any problems with the HVAC system before they leave the jobsite.

To use CheckMe!, technicians must attend a full-day, hands-on training, and they have to go back and correct any issues detected during on-site inspections following the installation.

Meanwhile, Building America continues to support multifaceted research and demonstration of new technologies and approaches to improving installed performance of HVAC systems in American homes. “We believe advanced HVAC fault detection and diagnostics will lead, over time, to business-friendly solutions that will significantly improve HVAC system reliability and substantially reduce energy costs for millions of households,” Building America’s Werling says.

Juliet Grable writes about the built environment, energy, climate change, species conservation, and environmental restoration. She lives in southern Oregon.