www.pathnet.org

|

www.pathnet.org

|

From California to Florida, North Dakota to Louisiana, storms pound the homes you build — to what effect? We've chosen August, the high noon of hurricane season, to focus on the forces of wind and water, research on disaster resistance in building materials, and building practices you can adopt to improve your homes' odds of weathering major storms.

Inevitably, we see images of the most dramatically damaged housing spooled across the television screen after a major storm. The more common types of storm damage might make for less interesting television, but they are instructive in identifying points of special vulnerability that can be mitigated with closer attention to design, material selection and inspection issues.

Hurricane Andrew delivered a pointed message on roofing in 1992. Its 165-mph gusts inflicted moderate to severe damage to roofing in 77% of the homes in its path. More than 60% of the homes lost one or more roof sheathing panels. Few escaped without water penetration, with damage to interior finishes reported in a staggering 85% of the homes, according to a study by the NAHB Research Center.

Tornadoes offer an even starker picture of the effects of high winds. In its study of the effects of a category F4 tornado that hit La Plata, Md., in 2002, the Research Center reported that most observed failures related to roof, wall and foundation connections and their resistance to wind uplift loads. Preventing damage in the vortex of a tornado is virtually impossible, but mitigation measures for hurricanes and tornadoes share some similarities.

Building for the Big One in Florida

Concern for disaster resistance is perhaps nowhere more acute than in Florida, where PATH is teaming with Mercedes Homes, the Federal Emergency Management Agency, the University of Florida and Fannie Mae to develop a new standard in hurricane-resistant construction.

In this project, which builds on earlier work by the Consortium for Advanced Residential Buildings — a U.S. Department of Energy Building America team — PATH is working to make poured concrete homes that better resist hurricane-force winds. In a comparative study of poured concrete and concrete block homes, PATH researchers found that poured concrete walls are quicker to construct and better resist wind loads. The team is examining how to exploit the solidity of the poured concrete walls to enable homes to weather a major storm.

Now in the process of finalizing its upgrade recommendations, the team found that the Mercedes units required a surprisingly small additional investment in the concrete wall system to withstand the 125-mph wind-force goal established by project partners at the University of Florida. Design protocols call for extra tie-downs and alignment of the bearing walls with the truss tie-down points to create a direct load path configuration.

Essentially a planning issue, these adjustments represent less than $10 in additional costs. Similarly, additional steel costs average about $13, primarily for reinforcing around windows and sliding glass doors. And with another nominal cost increase to cover a deeper reinforcing member, the team found that the wall system could reach 135-mph wind resistance.

Roofing enhancements and removable steel shutters cost more. Shutters for a 2,400-square-foot, single-story home with 312 square feet of windows come in at just less than $700.

In evaluating the weak elements in the roofing system, the team considered other research that suggested increasing roof decking to 3/4 inch. However, PATH results indicate that 7/16-inch oriented strand board is adequate for the 125-mph goal. Perhaps most surprising, the team found that the nailing pattern specified by existing codes is adequate for high wind loads.

Roof covering, the team found, was the real issue, as asphalt or fiberglass shingles often blow off during a storm and expose the sheathing underneath to wind and water. The seams between the deck sheathing allow water to enter the home, even when the entire roof structure remains intact. The best defense options are:

Once PATH technical advisers finalize the upgrade package, Mercedes will conduct a review before breaking ground on a strong home model. If funding allows, the model home will be outfitted with stress sensors imbedded in the concrete and at tie-down locations so the home's performance can be monitored through a high wind event.

"The preliminary results lead me to believe this is very conceivable," says Kirk Malone, vice president of construction for Mercedes. "We're pretty excited about it."

PATH hopes to encourage wider use of poured concrete. "There's no reason you couldn't build poured concrete homes in harsher climates," says Bill Zoeller of Steven Winter Associates, a PATH contractor involved in the project. He notes that poured concrete is viable anywhere slab-on-grade houses are built, with the exception of high seismic areas.

Laminated rigid foam insulation on the interior wall side of the poured concrete offers an unbroken thermal layer. Assuming the attic is sealed and insulated appropriately, the homes are virtually airtight. And although more wind-resistant and faster to build, poured concrete homes sell for the same as traditional concrete block houses.

While researchers still are working on design improvements and models that accurately predict how light-frame homes behave during extreme wind events, here are a few key recommendations from the PATH report "Durability by Design" and Vladimir Kochkin of the NAHB Research Center:

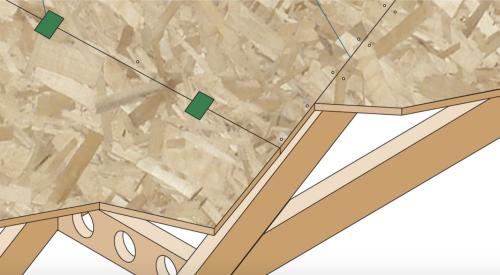

Continuous uplift load path and anchorage: In hurricane-prone areas, use hurricane ties or clips to connect the roof to the wall system. Line up bracing and truss tie-down points, and anchor each level to the level below. Use light-gauge steel straps to anchor the first story to the foundation. (During Hurricane Andrew, hurricane ties had a 92% success rate.)

Wall bracing: Proper diaphragm and shear wall construction using a rated bracing material such as oriented strand board or plywood is critical.

Construction practices with durability in mind: Material durability is key to future disaster resistance. Also, attention to small details — lapping wall top plates at intersections with interior walls and attaching sheathing to a common stud in corner construction — can make all the difference, according to full-scale shear wall testing done by the NAHB Research Center.

Proper nailing schedule: Size, type and placement are all factors. Inadequate nailing schedules in older building codes were implicated in the widespread roof sheathing damage in Hurricane Andrew. Preliminary findings of an NAHB Research Center study suggest that nail edge distance tolerance is quite tight (acceptable nail edge distance should be 1/4 to 3/4 inch) and that nail overdrive can reduce uplift strength of the connection significantly. Thicker sheathing can offset sensitivity to overdriving. When inspecting roof sheathing nails, attention to a gable end truss is especially important.

Ring-shank nails: To secure sheathing panels in hurricane-prone areas with basic wind speed of 110 mph or greater, ring-shank nails are recommended for their higher withdrawal capacity. Costs are comparable, and with a slightly smaller diameter, they offer the added benefits of less frequent reloading of pneumatic nail guns and more forgiving edge distance tolerances.

Wind-borne debris protection: Reduce forces on the structure and minimize water- and wind-related damages to the interior by protecting windows with approved shutters or properly fastened wood structural panels in coastal homes that might experience a hurricane.