Properly applied framing techniques make a big difference in getting homes to zero energy performance, not only by reducing the amount of framing in stud-framed construction, but also by improving the thermal performance of the walls. This provides more room for insulation and reduces thermal bridging—the heat loss that happens 400% faster through wood framing than insulation.

RELATED

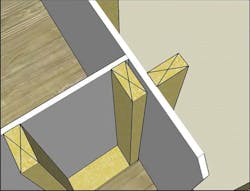

Continuous drywall at interior partitions

Drywall typically serves as the interior air barrier for the home, but the corners where interior walls intersect with exterior walls are often weak spots where the insulation is replaced by framing. Home Innovation Research Labs tested an approach to installing drywall continuously along the inside of the exterior walls of the home. To do this, all interior walls are framed with a ¾-to-1-inch gap between the interior wall and the exterior wall. The interior wall framing is anchored to the top plate with flat plate connectors to stabilize the assembly. At the drywalling stage, drywall is slipped through this gap as it is installed along the interior side of the exterior walls in one continuous path, mitigating the need for wood studs at the corners. Then, interior walls are drywalled. The drywall sheets along the exterior walls are installed so that seams do not align with room corners. This simple technique eliminates a significant thermal hole at all interior/exterior wall intersections in stud-framed walls.

Rim joist window headers

In two-story homes, the space above the first-floor windows and doors is often composed of solid wood to structurally support the building load. Studies by Home Innovation Research Labs has shown that the rim joist for the second floor, which typically sits about 1-to-2 feet above the window frame, can be used as is or reinforced to provide adequate structural strength to support building load, so no additional framing other than the king studs on each side of the door or window is needed to carry the load. The space above the door or window is left open and can be insulated like the rest of the wall, and the rim joist can continue to be fully insulated with no disruption. This technique makes use of the rim joist already present for structural support, saving time, labor, and materials costs while adding to the overall thermal performance of the wall.

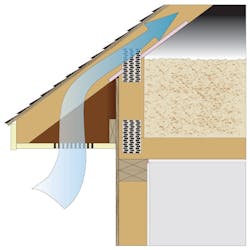

Continuous sheathing for raised heel trusses

For builders accustomed to building with standard trusses, using raised heel trusses could seem complicated, time-consuming, and expensive. Concerns about adequate support led builders to install blocking at each rafter bay to hold the trusses in place, which is a difficult, labor-intensive job. However, Home Innovation Research Labs found a simpler solution: installing oversized OSB wall sheathing that extends up along the back of the raised heel, providing bracing for the trusses. The sheathing layer doubles as a wind baffle, allowing the insulation to fill the space above the outer walls to full height without spilling over into the soffit vents. Ventilation air flow is still provided through the air space between the top of the insulation at the roof rafters and the underside of the sheathing. This solution saves time and money by eliminating the separate steps of installing blocking and baffles. The only additional cost is the purchase of taller OSB panels, but 9- and 10-foot lengths are readily available. This technique is easier to air seal than other raised heel truss approaches and also provides some wind-uplift resistance as the roof truss is more firmly tied to the wall.