Tiled showers offer endless possibilities for homeowners and builders when designing bathrooms, with an array of colors and sizes available at their fingertips. Ready to be customized, tiled showers—ceramic and stone in particular—are also durable, easy to maintain, and hygienic. However, their assemblies are not inherently waterproof and should be installed with a system that effectively manages moisture in order to prevent mold growth and damage to moisture-sensitive materials.

Traditional Methods

Traditional tiled shower installation methods—whether at the base or wall—have multiple steps that often call for more labor and installation time than what newer approaches will require. Typical pan liners placed over the subfloor are not designed to allow for direct application of tile, so a mortar bed needs to be used for load distribution and bonding with the tile covering. The mortar bed will also need to be sloped to the weep holes in the drain, so that moisture will not saturate the bed itself and increase the risk for efflorescence, grout discoloration, or mold growth.

For shower walls, most traditional systems will require a vapor retarder, such as roofing felt, reinforced asphalt paper, or polyethylene sheeting, installed over the studs and lapped over the pan liner. Tile backer boards may be supplied and installed by the gypsum board installer or tile contractor. Typical boards, such as cement board underlayment or fiber-cement board, are water-resistant but not waterproof, so the risk remains for moisture to infiltrate into the mortar base.

Newer Approaches

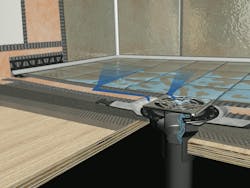

Bonded waterproof membranes were introduced in the 1980s and adhere directly to the substrate, allowing for direct application of the tile. The Schluter system uses a modified polyethylene sheet-applied membrane, with a bonding fleece embedded on both sides. This membrane can be installed over a sloped base and shower drain with integrated bonding flange using thin-set mortar. Should traditional clamping drains already be in place, the system also includes an adaptor kit for converting into integrated bonding flange drains, which provide a large contact area for watertight connections between the membrane and the top of the drain assembly.

Shower assemblies using approaches like the Schluter system work well because they do not allow moisture to penetrate into a mortar bed. This allows the assembly to dry completely between uses, eliminating the risk for mold growth in the shower area. Using preformed shower trays with built-in slope is also an option with the Schluter system, removing the need to set a mortar bed entirely and potentially saving contractors a significant amount of time. Preformed trays typically can be tiled immediately.

Overall, bonded waterproof assemblies offer the opportunity to eliminate several steps from shower construction and greatly reduce the risk for mold growth and damage to moisture-sensitive building material. Instead of needing to prepare shower walls with a vapor retarder or shower bases with pre-slope, tile coverings can be placed more quickly and efficiently.

To read the full white paper comparing traditional showers to bonded waterproof assemblies, visit www.probuilder.com/tiled-shower-waterproofing-systems