The pandemic has significantly impacted builders’ views toward offsite construction. That’s a key finding from recent surveys conducted by Home Innovation Research Labs, an independent subsidiary of the National Association of Home Builders (NAHB).

While almost three quarters (72%) of surveyed builders say the pandemic has had no effect on how they view offsite, almost one in five (19%) say they look at offsite more favorably as a result of the pandemic. That’s 10 percentage points higher than the builders (9%) who say they now look at offsite less favorably.

On its face, that might not seem like a huge shift, but it’s bigger than it might seem when considered in the context of the slow-to-change construction industry, says Ed Hudson, director, Market Research Division, Home Innovation Research Labs.

“In the construction industry, 10 percentage points is a sizable change,” Hudson says. “Overall, based on our studies, we’ve seen that the post-covid market has caused an uptick in the desire for offsite technologies.”

(On June 9, Hudson presented the complete findings from the Home Innovation Research Labs' research. His report, Changing Preferences for Building Products in a Post-COVID Market, is available for free download here, or by clicking the "Download the Report" button at the bottom of this article.)

Why Builders Are Choosing Offsite Construction Now

There are two main reasons for that increase in builder interest in offsite construction methods, Hudson finds:

Supply chain challenges

Amid the notorious pandemic-era problems in the supply chain, builders have looked for a more streamlined way to secure their materials. One way that can be achieved is by having a single offsite supplier, instead of procuring onsite products from multiple suppliers. With onsite construction, it can take months to order supplies. That longer lead time also means greater price volatility. Onsite construction also takes more time to assemble the materials and erect the structure than offsite construction. By contrast, it typically takes just days to put up a house built offsite.

Labor crunches

The availability of labor has gone down, and the cost of it has gone up for builders. The shortages and rising costs of skilled labor in particular have made offsite more enticing. With offsite, much of the skilled labor becomes automated in the factory. It takes greater skill (and time) to become a good carpenter than it does to learn how to operate equipment of offsite construction, Hudson notes.

In March, 24% of surveyed builders said they plan to lessen the impact of the skilled labor shortage by adopting construction practices that use less skilled labor—a figure that’s up from 19% pre-pandemic.

Top 3 Places Where Builders Opt for Offsite Construction

Builders plan to adopt offsite construction methods for some tasks on the jobsite, but not others. Here are the top three spots where builders choosing offsite for their new homes.

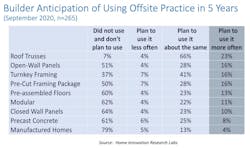

- Roof trusses: In July, more than one in five (22%) say they plan to use offsite more often for roof trusses—up from 15% two years ago.

- Turnkey framing services: 19% of builders say they plan to use offsite more often—up from 7% two years ago.

- Precut framing packages: 14% intend to use offsite more—a modest bump over 12% in 2019.

Still, overall adoption remains low. In 2019, only 3% of single family homes were built using offsite construction methods.

So what needs to happen for more builders to adopt this practice? In brief, there needs to be more of it. “The biggest issue now is there isn’t the capacity for builders to switch to offsite,” Hudson says. “If everybody wanted to switch tomorrow, it would be impossible because there’s insufficient supply.”

RELATED: Architect Pushes Design Limits of Modular Housing

Builders tell Home Innovation Research Labs that they don’t have enough local providers of offsite solutions, so they’d have to pay more to transport offsite materials to their construction sites. “If there were more reliable local providers of offsite, more builders would switch to it,” Hudson says.

Another obstacle to wider builder adoption of offsite methods: They are wary of putting all their eggs in one basket when it comes to labor and materials. If a project has just one primary supplier and that supplier encounters a problem, the entire project can get delayed. But if there are multiple suppliers and there’s a problem, say, with lumber, the builder can turn to other lumber vendors. While dealing with the multiple suppliers involved in onsite construction can be cumbersome and less efficient, builders also see it as a less risky approach than relying on a single supplier as they would for offsite.

Again, the answer is greater capacity, Hudson says: “When there’s an ample and reliable supply of offsite, then builders will gravitate to that solution.”