As labor challenges abound and schedules remain tight, trimming inefficiencies out of your installation processes can add up to critical time and money savings. Every contractor has their tricks for eliminating wasted steps without sacrificing a quality install.

Here are a few to consider.

8 Tips to Reduce Jobsite Inefficiencies

1. Leverage available accessories

When installing vinyl siding, be sure to leverage available accessories that can reduce detail work while ensuring a finished look. Some of the options from Westlake Royal Building Products include:

- Dual undersill trim: This is used the same way as standard finish trim, such as under windows or at the top of the wall, but because it has two slots instead of one, there’s no guesswork as to whether you need to bump out the finish trim to keep the siding angles correct.

- Board and Batten Trim: Use this to separate the courses of vertical siding since the profiles can’t overlap at the seam. The Board and Batten Trim has built-in flashing, making installation easy as well as functional.

- Shake Finish Trim: Designed for Westlake Royal Building Products’ Portsmouth Shake Panel, Shake Finish Trim secures ripped panels under windows and doors or at the top of a wall. Use a snap-lock tool to create snap lugs about every 6” to 8”, then snap the panel into the Shake Finish Trim and lock the snap lugs into place securely.

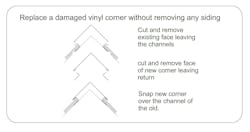

2. Replace damaged vinyl without removing siding

If you have a damaged vinyl corner, you can replace it without removing any siding. Cut and remove the existing face, leaving the channels. Cut and remove the face of the new corner, leaving the return. Then snap the new corner over the channel of the old.

3. Use a wooden jig for pre-drilling

For deck stairs, Fulton Fine Woodworks created a wooden jig that fits between the deck boards and shows precisely where to pre-drill for screw placement, eliminating the need to measure.

A post shared by Ronnie Fulton (@fultonfinewoodworks)

4. Measure from the foam, not the panel

When installing CraneBoard Solid Core Siding insulated vinyl siding, keep the ends of the foam no more than ¼” from each other to retain the insulation value, while giving the panels enough room to expand and contract. Pull and use your measurements from the foam instead of the panel. Both the panel and the foam will be the correct length.

5. Learn tape measure tricks

Need to find center but working with an uneven number? Simple rotate your tape measure, like so:

A post shared by Hammr (@wearehammr)

6. Make use of makeshift tools when needed

Tim Uhler, lead carpenter at Pioneer Builders, often creates makeshift tools that can do tasks more quickly while reducing user strain and fatigue. For example, instead of bending to cut sheathing while framing walls on the ground, he mounted a floor scraper to a router with spiral bit:

A post shared by Tim Uhler (@awesomeframers)

7. ... Such as this plywood rig

To lift heavy beams into place, Uhler made a beam wrench out of plywood:

A post shared by Tim Uhler (@awesomeframers)

8. Prevent bleed-through with hairspray

When painting trim, Robert Cripps Construction sprays aerosol hairspray on the painters tape, helping to prevent bleed-through.

Want more pro tips? Check out Westlake Royal Pros’ compilation on Instagram.

Westlake Royal Building Products’ portfolio of siding, trim, stone, and roofing brands offers a diversity of styles and options to meet your buyers’ needs. Click to explore: