The Basics of Process Improvement, Part 1

PDCA and DMAIC.

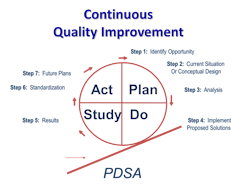

One of the most basic things to understand about process performance improvement is the Deming Cycle or Plan, Do, Check and Act (PDCA) This is also referred to as the earlier Shewhart Cycle which is Plan, Do, Study and Act.

The plan–do–check–act cycle is a four-step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for the foundation of continuous improvement.

- P Plan:Identify an opportunity and plan for change.

- D Do:Implement the change on a small scale.

- C Check:Use data to analyze the results of the change and determine whether it made a difference.

- A Act:If the change was successful, implement it on a wider scale and continuously assess your results. If the change did not work, begin the cycle again.

Take a look at the below link for more information and an example.

http://www.asq.org/learn-about-quality/project-planning-tools/overview/pdca-cycle.html

While PDCA is the most fundamental aspect of quality and can be used everyday in every process we do, DMAIC (from Six Sigma) can be used as a project management tool to drive improvement teams to root out and eliminate the causes of defects.

Define a problem or improvement opportunity.

Measure process performance.

Analyze the process to determine the root causes of poor performance; determine whether the process can be improved or should be redesigned.

Improve the process by attacking root causes.

Control the improved process to hold the gains

Take a look at the below link for more information and an example.

http://www.asq.org/learn-about-quality/six-sigma/overview/dmaic.html

NEXT TIME, Part 2 Quality Tools and Links to FREE Templates