Q+A With Brent Wadas: How BotBuilt Is Automating Home Construction

Brent Wadas came into the construction industry as a military veteran and entrepreneur. Frustrated by labor shortages and the way labor is generally treated in the U.S., he co-founded BotBuilt, in Durham, N.C., in late 2020 with chief technology officer Barrett Ames and chief operating officer Colin Devine.

In a nutshell, the company seeks to revolutionize housing production using robotic systems cast off by the auto industry and powered by proprietary software to build framing components, including wall panels and engineered trusses, with greater precision and in a fraction of the time and cost of stick-building.

But BotBuilt’s ultimate goal is even more far-reaching: They’re out to solve the housing crisis once and for all and to end homelessness.

PRO BUILDER: What led to BotBuilt?

Brent Wadas: Barrett Ames, Colin Devine, and I worked with a lot of builder networks and put together a business plan to be able to operationalize robotics in construction. Katerra was still around back then and it was becoming this monster of inefficiency. I just thought there has to be a better way.

Barrett’s better way was creating flexibility in manufacturing with software. Rather than spending $15 million on a machine, we chose to invest in software that can turn any basic floor plan into a three-dimensional model that can be fed to a robotic system. That approach makes it accessible for every builder to use robotics, not just those that have access to tens of millions of dollars.

PB: What is BotBuilt’s role and process?

BW: Our system provides framing components—wall panels, roof-truss systems, sheathing—for any type and style of home.

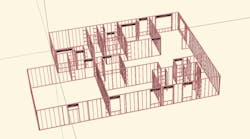

Typically a builder sends us a basic, two-dimensional plan of a house. It takes a few minutes for our software to read and evaluate what that plan looks like, and from there it models a three-dimensional image of the framing plan. That 3D model shows us every piece of sheathing, every nail, every stud placement, and every header. We then input builder constraints and specifications for the project into the computer to refine the model.

Next, the 3D model is turned into a digital book of panels to produce, which is sent to a setup of two robots, each on a rail system, to build them.

In a way, the robots are autonomous. They dictate their own processes in an order that makes sense to them. We don’t have to reprogram the entire system for each project.

PB: What’s the technology of the robotics?

BW: The system is a collection of industrial robots; machines that are usually used on assembly lines to build cars. They have the capability of lifting anywhere from 160 to 210 kilograms—about 350 to 400 pounds—fully extended out.

But their untapped potential is that they’ve been built to make very precise movements for large-scale auto manufacturing. Once they are 0.2 millimeters out of precision, they are rendered useless for that industry ... but still well within tolerances for home building.

RELATED

- Modular Home Building Pioneer Veev to Shut Down

- Housing, Industrialized: Marketing to Consumers

- Florida Multifamily Housing Complex Built Using Lego Block–Like System

We buy them up and use our custom tooling systems, including 3D printers and CNC machines, to adapt them for construction using proprietary technology from our hardware division. The software we built interfaces with those tooling systems to build in the most efficient manner possible.

PB: What is BotBuilt’s ultimate goal and where are you currently in that journey?

BW: Once the system is fully tested and scalable we’d like to start expanding into full home builds.

Our vision is to bring the system to the jobsite instead of operating it in a factory and to have multiple robot lines running at the same time so we can supply framers without having conventional materials logistics as a constant concern or constraint.

Though housing production and labor are important to us, BotBuilt’s overarching mission is to end homelessness. I’ve witnessed the dearth of housing options that will hurt our younger generations who aren’t given access to the same type of generational wealth I was privileged to receive. The only way we’re going to address that is through supply-side solutions that allow us to build more efficiently so we enable more people to not just have a home but to build generational wealth.