Residential windows and their installation have evolved over time. Gone are the counterweights for operable sashes and the cleverly crafted divided lites with single-pane glass … and the time and skills required to create them.

Today’s windows utilize modern materials and sophisticated manufacturing techniques that eliminate several steps of an old-school installation. But just because every component of a pre-hung window unit is integrated doesn’t mean it’s any easier to install. In fact, proper pre-hung window installation is highly prescriptive and deceptively complex, and failure is not always immediately obvious.

Careful Detailing to Eliminate Air and Water Leaks Around Windows

Protecting against air and water leakage requires careful detailing. Case after case of reported window failures, specifically regarding window flashing and water intrusion resulting in everything from indoor air quality issues to structural problems, suggest that the sequence of modern window installation isn’t as easy as it seems. Fortunately, there are ample illustrated references of proven tactics that ensure a quality job—namely inside each shrink-wrapped window and from building science wonks like us.

But instead of rehashing every step of a window installation here, let’s focus on the sill. Why? Because proper sill pan flashing will protect the framing and drain any water that breaches the rest of the window assembly, such as cracks in vinyl window welds or improperly applied jamb and head flashing. Simply, the sill is your last line of defense against big problems.

RELIABLE

- How to Waterproof Recessed Windows in Concrete Block Walls

- Proper Flashing for Recessed Windows

- Making Sure Doors Are Watertight

- Proper Flashing Practices for Fascia

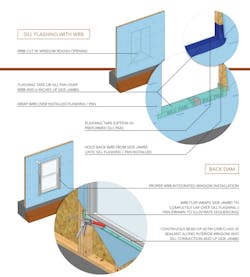

You basically have two options: A preformed sill pan or flashing tape. A preformed pan should include all the necessary elements, such as vertical legs at the jambs, a back dam, and maybe even slope to the exterior. Flashing tape, meanwhile, requires the installation of a continuous piece of flexible, self-adhesive flashing membrane that wraps the entire sill, including the front and back edges and 6 inches up the sides.

And, once the window is installed, you need to create a back dam with a continuous bead of sealant along the interior connection of the window unit along the sill and up each jamb to block any incidental water that may intrude into the assembly.

Window Flashing: Sill Flashing Best Practices Checklist

If anything, remember this: Proper sill flashing needs an end dam to ensure any water that does reach the sill flashing is forced to drain to the outside. Another crucial rule: Make sure the bottom nailing flange of the window unit is NOT sealed, so that any trapped water can drain to the outside.

Use the illustration and follow this best-practices checklist to deliver a quality window-sill flashing assembly with an integrated water-resistive barrier (WRB).

1. Cut the WRB

Cut diagonals from the center of the rough opening to the bottom corners and extend the cuts 3 inches horizontally from each corner.

2. Secure the pan

Integrate a preformed pan with the WRB or cut a continuous length of flexible self-adhesive flashing tape that is wide enough to cover the sill framing and extend 6 inches up each side jamb. Start at one jamb and carefully expose the adhesive side as you go to eliminate voids and wrinkles.

3. Install the window

Follow the window manufacturer’s instructions for a proper WRB-integrated assembly.

4. Create a back dam

Once the window is installed, apply a continuous bead of ASTM C920 Class 25 sealant along the window unit’s interior connection to the sill and 3 inches up each jamb.

Richard Baker is program manager of the Builder Solutions team at IBACOS.