The Consumer Product Safety Commission estimates that deck collapses have sent about 4,600 people to emergency rooms over the past decade. The most common type of collapse reported was a deck pulling away from the house.

If that makes you suspect problems with deck ledgers, you’re right. In a nationwide survey published by the International Code Council (ICC) in 2013, building officials identified inadequate deck ledger connections as the most common deck-related code violation (cited by 62 percent of respondents).

RELATED

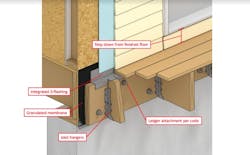

Proper attachment is crucial. The International Residential Code (IRC) bases its ledger-fastening schedule on joist length because the joist length determines the load. The builder need only consult the table in the code to see how many bolts or lags to use and how far apart to space them. It’s important to note that there have been changes in the fastening schedule and allowable joist length, depending on your governing code. We recommend referring to Section R507 of the 2015 IRC for the most recent requirements, including those put in place to reduce the effect of lateral loads. A hardware tieback that consists of brackets bolted to the deck and floor joists and joined by a threaded rod that passes through the band is one strategy for resisting lateral loads.

Be fastidious with flashing. Respondents to the ICC survey named decks as the second biggest offender when it comes to flashing violations. This is serious—even the most carefully bolted deck can pull away if the ledger connection has rotted.

The flashing must integrate with the home’s water-resistant barrier (WRB). With standard plywood or OSB sheathing, this is a simple matter of lapping the WRB (typically housewrap or building paper) over the Z-flashing that sits atop the ledger. When using a sheathing product with a WRB integrated on its surface, you’ll need to seal the flashing’s top edge with the manufacturer’s recommended tape. Incorporating an additional piece of flashing below the ledger is a best practice to allow any incidental water from behind the ledger board to drain away.

It’s also good to install peel-and-stick self-healing membrane on the wall behind the ledger to seal around bolts or lags. Shingle the membrane’s top edge under the WRB and lap its bottom edge over the flashing below the deck. A granulated surface on this membrane is preferable to a smooth surface, as it will create tiny airspaces that help the ledger dry out more quickly.

Use the illustration above and the checkpoints below to mitigate some common issues with deck ledger boards.

• Secure the ledger per code requirements, including threaded tiebacks for lateral bracing (not shown).

• Integrate Z-flashing above the ledger with the WRB.

• Use properly sized joist hangers to secure the deck joists. Don’t toe-nail joists to the ledger.

• Using a granulated membrane behind the ledger will seal around fasteners and help the ledger dry out.

• Provide a step down from the finished floor to the deck surface. This will reduce the potential for wind-driven rain or melting snow to work its way under the door threshold.

Richard Baker is program manager of the Builder Solutions Team at IBACOS.