When it comes to stucco, there are details most contractors get right, and other details that some contractors get wrong. For instance, pre-application details, like those associated with lath fastening, are often done properly, which is really no surprise, as they are prescribed by code and subject to inspection.

Common Stucco Problems

On the homes I assess for construction quality, I see more problems with the stucco itself.

Crews working in hot weather add too much water in a misguided attempt to keep the mix from drying too fast. Others don’t use the right type of sand, or they use sand that has been contaminated with native soils after being dropped on bare ground by the supplier and then shoveled into the mixing bin.

If the stucco’s sand-to-cement ratio is incorrect, it can increase the chances for surface cracking. Native soil in the sand can weaken your mix, resulting in bigger cracks in the stucco or blemishes on the finish.

Make them replace the sand and place it on a proper separator. Do that, and it won’t take long for the supplier to do it right the first time.

I also commonly see inconsistent thicknesses in the scratch, brown, and/or finish layers caused by crews improperly leveling the coat on the wall. In fact, I’ve seen the metal lath behind the scratch coat clearly visible even after the brown coat is applied.

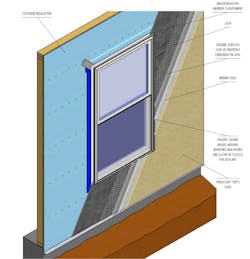

In addition, ill-informed and improperly trained crews push stucco into the gaps between the casing bead and the window or door trim, which is intended for sealant where these dissimilar materials meet. Many don’t know why the gap is there.

RELATED

- How to Keep Stucco From Cracking

- One-Coat Stucco Basics—6 Common Problem Areas

- What Is the Cost of Quality Construction?

What Causes Stucco Problems

These problems have the same underlying cause as most construction defects: inexperienced crews that lack good training and supervision. And the remedy is the same: a system to make sure the work gets done right.

Sand problems

Your instructions to the stucco mix supplier should clearly state that it will conform to the appropriate ASTM specification.

You also should require that loose sand be placed on plastic or some other soil separator.

The builders that don’t have sand problems are the ones who, when the supplier fails to follow these instructions, make them replace the sand and place it on a proper separator. Do that, and it won’t take long before the supplier does it right the first time.

In fact, many builders now specify bagged stucco sand, as it almost completely mitigates soil contamination and helps ensure a fine-tuned sand-to-cement ratio in your stucco.

Stucco hydration

Another important aspect is hydrating the stucco once it is applied to the wall, especially in hot, dry climates.

To prevent stucco from drying too quickly and not fully curing, require the stucco contractor to moist-cure it with a simple garden hose on a light spray setting for a couple of days after application.

Stucco thickness

Proper thickness can be ensured by spot checks with a thin measuring tool. The stucco contractor is supposed to do this, but you can keep everyone motivated with random, surprise thickness checks of your own in a couple of spots. You may not have to do it on every house, but every crew needs to know that you check.

Experienced crews will execute all of the above without your intervention because they don’t want to come back and fix cracks and other problems. But new, inexperienced crews may not have gotten that memo yet, so you need to make sure they do ... and follow through.

The bottom line is that—as with just about everything on the jobsite—the best way to ensure trouble-free work is with a good quality control program.

Richard Baker drives quality and performance in home building as a building performance manager on the PERFORM Builder Solutions team at IBACOS.