To reduce lumber waste, you have to go well beyond mere scraps. While a dumpster full of “scrap” lumber is the most visible example of waste, its impact is far greater if you consider the money spent on excess lumber ultimately not needed for construction—especially given the volatility of materials costs today.

Excess wood is less visible, so it’s often overlooked. But making it a priority will save money, time, and effort while reducing hauls to the landfill. The secret is to be mindful of how you frame certain details, how you order lumber, and how that lumber shows up on site. Here’s how.

Easy Advanced Framing Details to Reduce Lumber Use and Reduce Lumber Waste

We’ve covered optimum value engineering (OVE, aka advanced framing) in this column before, but the techniques always bear repeating as an effective way to reduce lumber use and reduce lumber waste, among other benefits.

Simply, OVE places rafters, joists, and 2-by-6 studs 24 inches on center and vertically aligns framing members to create direct load paths from roof ridges to footings, eliminating the need for double plates and reducing the number of load-bearing window and door headers. All told, using OVE can save about $1,000 in lumber costs for a 2,400-square-foot house, and can help builders complete it in less time, saving additional costs.

RELATED

- Wall Framing Techniques to Improve Thermal Performance and Lower Costs

- Framing in a Time of Shortage

- Reducing 3 Types of Construction Waste to Increase Home Builder Profit

Even so, few builders fully embrace this approach and still use 2-by-4s at 16 inches on center. But the beauty of OVE is you can adopt certain aspects of it and still benefit. For instance, I see more of our builder clients using three-stud “California” corners to reduce lumber in that area of the frame.

Builders average a 15% waste factor on framing jobs.

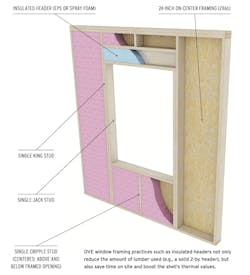

A good next step would be insulated headers, which replace a layer of lumber with rigid foam insulation (which also reduces thermal bridging through the header), and reduces the number of jack studs and cripples around the window opening (see illustration, below). It goes without saying that the structural designer needs to approve the change, but since OVE is a well-documented and proven method, that’s not usually a problem.

Take-Off Tweaks to Save on Lumber Costs

I’ve seen plenty of framing lumber that wasn’t properly optimized arrive at the jobsite—a big reason why builders average a 15% lumber waste factor on their framing jobs.

Say, for example, that the roof of a small porch will need 10 2-by-6 rafters, each 7 feet long. If you order 8-footers and cut 1 foot off each one, you’ll end up with 10 feet of 1-foot scraps. But if you order five 14-footers and cut them in half, there is zero lumber waste.

Optimizing lumber lengths for an entire home will require some effort by the estimator, but most production companies build a handful of designs multiple times, which results in economies of scale whereby the rewards will be multiplied—as will the costs of continuing to ignore the inefficiency of wasted lumber.

Site Adjustments for Optimizing Lumber Quantities

For the estimators to properly optimize lumber and reduce lumber waste, they need feedback from the jobsite.

In many cases, I’ve seen take-offs include 10 more sheets of OSB than the job requires. While some of that OSB may ultimately get returned to the supplier, much of it just clutters the site, ends up damaged and in the dumpster, or “disappears” in the back of a pickup truck. Instead, the site supervisor should confirm the required number of OSB sheets with the framers and then align with the estimator for the take-off. That extra bit of communication will result in a significant return.

None of these steps is difficult, and everyone wins in the end. Real cost savings, less clutter and cleanup, and fewer materials returns are just a few of the benefits. You may even find it motivates you to find more ways to save.

Andrew Shipp drives quality and performance in home building as a building performance specialist on the PERFORM Builder Solutions team at IBACOS.