The Right Way to Waterproof Recessed Windows in Concrete Block Walls

CMU walls are common in Florida and other parts of the Southeast, but the practice of recessing windows and doors into rough openings in concrete block walls creates a waterproofing challenge for home builders.

How to Waterproof Windows in CMU Walls

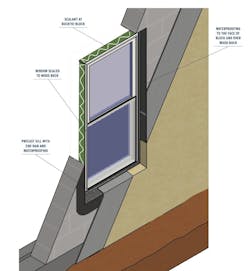

In short, those recessed areas become water traps for wind-driven rain and consequently require a two-step process that consists of applying sealant and liquid-applied waterproofing. And both steps have key details that absolutely must be done right.

Step 1: Apply Sealant

The first step is to seal the backs and edges of wood bucks at window and door openings using a high-grade ASTM C920 class 25 sealant. Apply the sealant to the back of the buck in a zigzag pattern, place the buck in the opening, and drive concrete screws through the buck into the concrete. Then run a second bead of sealant along the gap between the outside edge of the buck and the concrete.

The most common mistake I see here is not applying enough sealant. Many installers only apply a ¼-inch bead or less. But it takes it a 3/8-inch-to-1/2-inch-thick bead to create a proper seal over the irregular surface of the blocks.

RELATED

- Avoid Water Intrusion and Leaks: Penetration Flashing Done Right

- How to: Proper Flashing for Recessed Windows

- Mind the Gap—for Expansion, That Is

Step 2: Install Waterproofing

Next, apply a liquid concrete waterproofing membrane over the area. Block walls are almost always finished with stucco, so the membrane must be approved for use behind stucco to ensure a firm bond.

Why do you need this coating? Without it, capillary action will draw rainwater into the pores in the exposed concrete of the recess and that water will eventually get into the home.

The best-quality solution is to use two coats of waterproofing membrane. Apply both coats after installing the buck and extend it to the front edges of the openings.

Block-wall recesses become water traps in wind-driven rains and consequently require a two-step waterproofing process.

Some jurisdictions may require about 8 inches past the opening on all sides to allow for the opening and bucks to be fully waterproofed. However, two full coats are rare; some builders use just one and when two are used, the thickness is inconsistent.

The reason for the extent of waterproofing is that recessed windows and doors in block walls don’t have nailing flanges as with framed walls; instead, they’re screwed in place through the jamb. And although the gap around the window gets filled with low-expansion foam, that gap is a weak point for moisture intrusion. A buck coated with waterproofing is less likely to absorb water that can then make its way to (and into) the block.

LEARN MORE

A Few Waterproofing Do's and Don'ts

DON'T limit the extent of your waterproofing application:

A lot of builders simply (and wrongly) apply liquid waterproofing to the sill, then extend it only half way up the opening. They assume that the jamb is the most likely spot for water intrusion (which it is), but they forget that rain can drive water into any gaps around the window or door (which it most certainly will).

DON'T skimp on the thickness of the waterproofing application:

I also frequently see homes where waterproofing applied to the block looks splotchy after it dries. This is a sign that the block’s pores weren’t fully sealed because the installer was in a hurry and didn’t use a thick enough coat or didn’t work it into the surface. These homes are at high risk of moisture problems.

DO pay attention to the sill:

When installing windows, always use a three-step precast sill, which has an extra dam at the interior side of the sill, offering added protection against wind-driven rain.

Graham Davis drives quality and performance in home building as a senior building performance specialist on the PERFORM Builder Solutions team at IBACOS.