Preformed shower pans are used in many production homes because they purport to reduce installation time and errors.

But in our experience, installers regularly flub key water-management details with these handy products, namely improper flashing, sealing, and plugged weep holes. Here’s how to do them right.

RELATED

- Waterproofing Showers, Part 2: Site-Built Shower Pans

- Waterproofing Showers, Part 3: Glass Mat Backer Board

Flash the Shower Pan's Flanges

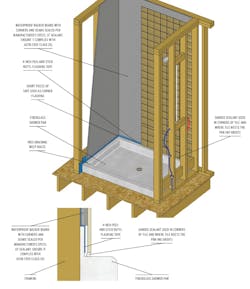

Before the backer board goes on, use 4-inch-wide butyl flashing tape (yes, window flashing tape) to flash the pan flange to the blocking between the studs (see illustration, below). Water will inevitably get behind the tile, but without flashing, it will find its way into the wall cavity.

It’s easy to see whether the shower pan flange has been flashed; what’s not so easy is making sure it was correctly detailed.

Shower pan corners are a potential weak point. Some installers stretch a single piece of tape across all three legs of the flange, but unless they push the tape tightly into the corners (which they almost never do), the tile contractor will end up cutting the tape so the backer board can lay tight at those corners. See the problem?

The solution is to use a separate 6-inch length of tape for the corner flashing. Use a scrap of lumber or a putty knife to push the tape tightly into the corner, being careful not to damage, cut, or rip it. Then flash each shower pan flange leg individually. You won’t see this detail in many installation guides, but it’s a simple, effective strategy to avoid water intrusion at this key location.

Seal the Backer Board

Most contractors do a good job of sealing the backer board in the shower, but the best practices bear repeating. Simply, the backer board needs a sealed surface to prevent it from absorbing water. Your choices are to:

1. Use a porous cement board such as James Hardie’s Hardie-Backer or USG’s Durock painted with a liquid waterproofing compound like RedGard.

2. Use a gypsum-based product like DensShield tile backer from Georgia-Pacific that comes with a presealed surface that allows the face to drain. This option has the added advantage of being lighter and easier to install than cement board.

Regardless of which option or product you select, the seams must be sealed. Use an ASTM C920 class 25 sealant prior to the liquid waterproofing for cement board and during the installation of face-draining gypsum board.

Don’t Seal Shower Pan Flange Weeps

Shower pan flanges are designed so there will be a small channel running horizontally behind the backer board at its base. The channel leads to weep holes at the pan’s front and/or back corners. Water that gets behind the tile will drain to the base of the wall, into the channel, and out of the weep holes into the pan and the drain.

Some tile installers apparently don’t understand how weep holes work because we see them filled with caulk on the majority of jobs we inspect. Don’t allow this. If you seal the weeps, then water trapped behind the tile is likely to end up inside the wall cavity over time.

The first sign of trouble will likely be a surface issue, such as bubbling paint just outside the shower. But by the time that appears, there’s almost surely a deeper (and worse) problem.

The solution, of course, is to train your tile setter and other trades not to seal the shower pan weeps. And don’t forget to make inspecting this detail part of your quality assurance checklist.

Tim Kampert drives quality and performance in home building as a building performance specialist on the PERFORM Builder Solutions team at IBACOS.

Access a PDF of this article in Pro Builder's July/August 2020 digital edition