Blog: The impact of the humble blower door test

Five major national energy home building programs, Energy Star, LEED for Homes, Environments for Living, Building Americas Builders Challenge and the National Green Building Standard all have as a core element of their programs the use of the Blower Door Test (ASTM Standard E1827). Due to this the simple blower door test has had a national impact in the building of millions of energy efficient homes. For example by just focusing on the Energy Star program, its impact has meant that over one million new ENERGY STAR qualified homes have been built to date. This has resulted in 325,616,146lbs of coal being saved and 638,598,741 pounds of CO2 have been avoided. (EnergyStar)

This simple test can produce a dramatically disproportional positive impact both in terms of the improvements it can provide to a home and in the low cost to run the test and in the low cost solutions that it can allow builders to implement. Often the first issue to be focused on is improving the thermal resistance of the building. In other words, increasing the R-value of the floor, walls, windows, doors and ceiling for example. However this is expensive. The air tightness of the building is often under emphasized, but can be even more important, improving the thermal air barrier, making the building air tight and this can be a much more cost effective initial approach. Indeed only when a building is appropriately air tight will thermal loss/gain through the component elements of the building become significant. By using the blower door test as part of measuring your air change rate if becomes a critical tool in evaluating and improving the performance of the homes you build. It also provides a direct reflection on how well and ‘tight’ your homes are being built! The blower door test can become a critical part of the Plan Do Check Act cycle in improving your homes.

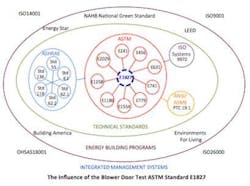

How does quality management come into this? The use of integrated management systems ISO9001 (Quality) ISO14001 (Environmental) OHSAS18001 (Safety) and ISO26000 (Social Responsibility) can become the infrastructure upon which an organization can manage how it functions and in particular how it manages its production management. Within this structure which drive efficiency and effectiveness of meeting the requirements of relevant energy building programs such as Energy Star. Within these programs are their specific requirements such as conducting blower door testing. To achieve this, the various technical standards need to be used at the core is ASTM E1827 but this is supported by a range of other ASTM standards and indeed associated standards such as ISO, ANSI and ASHRAE. In this way E1827 again becomes a central, fundamental aspect as shown in this diagram.

References

ANSI/ASME PTC 19.1- 2005, Measurement Uncertainly, Instruments and Apparatus

ASHRAE Standard 55 (2004) Thermal Environmental Conditions for Human Occupancy

ASHRAE Standard 62 (2001) Air Leakage Performance for Detached Single Family Residential Buildings

ASHRAE Standard 62.1 Ventilation for Acceptable Indoor Air Quality

ASHRAE Standard 62.2 Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings

ASHRAE Standard 119 Air Leakage Performance for Detached Single Family Residential Buildings

ASHRAE Standard 136 A method of Determining Air Change Rates in Detached Dwellings

ASTM E241-08 Standard Guide for Limiting Water-Induced Damage to Buildings

ASTM E456 Terminology Relating to Quality and Statistics

ASTM E631-06 Terminology of Building Constructions

ASTM E741-08e1 Test Method for determining Air Change in a Single Zone by Means of a Tracer Gas Dilution

ASTM E779-03 Test Method for Determining Air Leakage Rate by Fan pressurization

ASTM E1554-07 Standard Test Methods for Determining Air Leakage of Air Distribution Systems by Fan Pressurization

ASTM E1186-03 (2009) Practices for Air Leakage Site Detection in Building Envelopes and Air Barrier Systems

ASTM E1258-88 (2008) Test method for Airflow Calibration of Fan Pressurization Devices

ASTM E1827-96 (2007) Standard Test Methods for Determining Air tightness of Buildings Using an Orifice Blower Door

ASTM E2029-99 (2004) Standard Test Method for Volumetric and Mass Flow Rate Measurement in a Duct Using Tracer Gas Dilution

ASTM STP 1067 Air Change Rate & Air Tightness in Buildings

ISO9001:2008, Quality Management Systems Requirements

ISO9972:2006/Amd 1:2009 Thermal Performance of Buildings -- Determination of Air Permeability of Buildings -- Fan Pressurization Method

ISO14001:2004, Environmental Management System: Requirements with Guidance for Use

ISO26000: 2010 Guidance on Social Responsibility

OHSAS18001:2007, Occupational, Health & Safety Management System, British Standards Institute

Next Time Evenflow for Performance