Rethinking Scrap Culture: Innovations in Waste Management

Since the 1930s, a burgeoning consumer culture has given rise to what Royce Epstein, A&D Design Director of Mohawk Group calls the "Plastic Age," an era marked by the proliferation of lightweight, cheap plastic materials that have led to a waste crisis contributing to pollution and resource depletion.

In a recent webinar, Epstein posed solutions, some hypothetical and some already in progress, that explore the benefits of a circular economy in which manufacturers use waste as a raw material for production, reducing the need for virgin resources. Innovations in sustainable manufacturing have begun to explore the creation of furniture and building components from waste materials for more sustainable product alternatives in the design and construction sectors.

The Urgency of Change

According to a 2020 report from the Environmental Protection Agency (EPA), the most recent total generation of municipal solid waste (MSW)—which includes materials such as concrete, wood, asphalt, gypsum, glass, plastics, and more—was 292.4 million tons in 2018, or 4.9 pounds per person per day. Epstein says that this throwaway culture is made worse by standard practices of consumerism, which thrives on the premise of constantly replacing old products with new ones, generating waste both during manufacturing and disposal stages.

Additionally, Epstein claims that 80% of products are discarded within their first six months of use, resulting in an additional carbon footprint attributed to shipping and manufacturing.

“The product generates waste first in its manufacturing, but then it becomes waste within a year,” Epstein says. “Around 40% of a product's carbon footprint comes from shipping just for that short term use. The focus must be on how we can shift from our crisis of consumption to a different future, one where we reduce or even reject waste.”

Just as staggering is the waste generated from residential and commercial construction, accounting for 600 million tons of Construction and Demolition (C&D) debris in the United States alone in 2018, which is more than twice the amount of generated municipal solid waste.

But a few innovative manufacturers are finding ways to reduce both MSW and C&D waste by combining the two into useful building and design materials, working toward what designer and social scientist Dr. Leyla Acaroglu, 2016 United Nations Champion of the Earth recipient, calls a "post-disposable future."

How the built environment can adapt

The United Nations’ Sustainable Development Goals (SDGs) were introduced in 2015 as a universal call to action to end poverty and protect the planet from the effects of global warming by 2030. Dr. Acaroglu posed her post-disposable initiative in response to the United Nations Sustainable Development Goal #12, focusing on responsible consumption and production. This global movement seeks to rapidly redesign systems that perpetuate waste and pollution, emphasizing closed-loop approaches that give waste a new life.

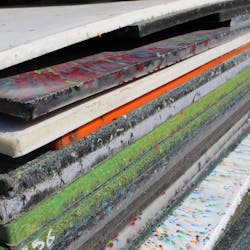

In the building industry, that concept is taking root in new product innovations from companies like ReFactory, which collects post-consumer use cosmetic containers to create high-impact medium-density fiberboard (MDF) and joinery boards. “MYBoards,” as ReFactory calls them, are manufactured from 100% waste plastic products with mixed polymer types.

ReFactory's MYBoards are made from 100% recycled plastic waste.

Image: ReFactory

“The larger story here is that over 100 billion cosmetic items are discarded every year,” Epstein says. “Cosmetics packaging is very challenging to recycle because it's usually made with mixed materials and it's tedious to separate, so many recycling centers won't take them, especially if they still contain makeup residue. There's a lot of post-industrial waste in this particular industry that typically just goes to landfill.”

The Plastic Flamingo, or "The Plaf," as it’s more commonly known, is a Philippines-based company that produces posts and planks called “eco-lumber” manufactured from plastic bottles and food wrappers collected across Asia. According to the company, “eco-lumber” is a 100% upcycled material made entirely from plastic waste, and unlike traditional lumber, it is “rot-free, maintenance-free, and splinter-free," says Erica Reyes, The Plaf’s chief operating officer.

Eco-lumber manufactured by The Plaf comes from plastic waste collected across Asia.

Image: The Plaf

Another eco-friendly building product innovation comes from Ecoworks, a German startup that uses laser scanning technology to create a digital twin of a building and produces prefabricated panels that form a “second skin” over the existing building, improving its insulation. Ecoworks uses wood for the paneling and cellulose for insulation, and it also fits a modular roof with built-in, repurposed solar panels. Ecoworks intercepts discarded solar panels and freshens them up to prevent valuable photovoltaics from ending up in landfills.