|

Heather McCune's Editorial Archives

|

The installation instructions for this custom home were a bit unusual: nine irons upstairs and cast iron downstairs. Make sense? Probably not. You see, the owner of this home in Pekin, Illinois had a dream: an indoor golf driving range on the second floor of his newly built 6000 square foot home. Creating such a space wasn't an issue; however, finding a way to create a comfortable, perfectly controlled climate throughout the rest of the home was.

| Patriot Heating and Cooling owner John Conway suggested a hybrid hydronic heating system for his neighbor''s 6,000 square foot home, which includes an indoor golf driving range.

|

The house features an 18-foot vaulted ceiling in the entryway, a great room with hard-wood and tile floor coverings, a whirlpool tub in the master bathroom, a big walk-out basement, and of course, the second-story indoor driving range. Heating these various living spaces evenly and comfortably challenged the homeowner, builder and heating and cooling contractor. After much investigation, the team settled on a hybrid hydronic heating system.

The heart of the system is a seven-section gas-fired boiler that provides 190 MBH input and has a through-the-wall direct venting option. Manufactured by Burnham Corp., the Revo-lution boiler selected for this custom home offers the type of versatility the job required. "This boiler does everything we wanted it to do," says John Conway of Patriot Heating and Cooling, subcontractor on the project.

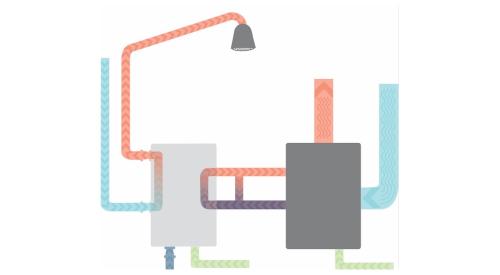

The boiler features a built-in injection pump and a primary/secondary loop. The injec-tion pump control constantly monitors the boiler water, which is important because the tem-perature of the return water from the radiant loop could be low enough to cause either thermal shock or flue gas condensation. The control, however, allows the primary/secondary loop to divert higher temperature supply water back into the boiler to avoid those problems.

The boiler supplies heated water to two radiant loops. On zone handles the home''s foyer and great room, while the other loop supplies the basement. Mixing values deliver 120°F water to the first floor loop and 100°F water to the basement loop. An individ-ual thermostat regulates each loop.

Elsewhere in the house, heat is provided by a hydro-air coil installed in an air-handling unit. One unit serves the first floor kitchen, dining room, sitting room and master bedroom and bath. The other unit serves the second floor with additional bedrooms, bathrooms and the golf room. The hydro-air coils are supplied by 180°F water. When heating, a blower circulated warm air off the hydrocoil fed by the boiler. The delta between the coil and the air is much higher than with a heat pump, so the supply air is warmer. When cooling, a dedicated refrigerant circuit functions just like any central air cooling system.

Another loop supplies an 80-gallon indirect water heater used for the whirlpool tub and other domestic purposes.

Total Control

Managing a hybrid system like this one with five zones and a thermostat for each zone is critical to ensure complete comfort. In this home, the builder and contractor selected an ARM and ARA Hydro-Air panel from Argo Industries. The system offered a clean, convenient panel design and boiler and air conditioning wiring that is virtually foolproof, while still allowing priority control of domestic hot water. A Smartway Solutions hydropanel was used for offsite monitoring of the system in real time.

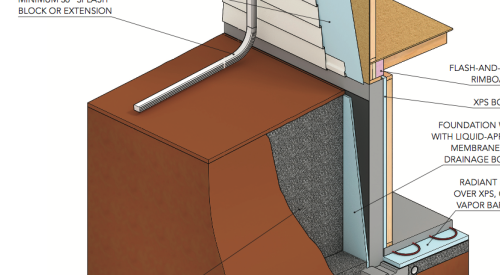

The builder and contractor worked together again to coordinate installations of the PEX radiant tubing in the basement''s concrete floor. The pipe was tied to the rebar, which was carefully hooked up as a four-inch layer of concrete way poured. For the first floor radiant loop, pipe was pulled through holes drilled in the trusses, then stapled to the subfloor. Instead of using reflector plates, six-inch, R-11 insulation was placed below the pipe to direct the heat upward.

Coordination and control between the builder and contractor resulted in a home and heating system the owner loves.

Heather McCune is the Editor-in-Chief for Professional Builder and Luxury Home Builder. Please email her with any comments or questions regarding her column.