Good ol' H2O is a tile setter's nemesis, with damaging results that can include mold, mildew, bacteria and efflorescence, as well as tile and substrate buckling, cupping, rotting or cracking. In today's air-tight construction environments, how do builders keep water, moisture and vapor from jeopardizing plans?

The Tile Council of North America's handbook describes a wet area as "either soaked, saturated or regularly and frequently subjected to moisture or liquids (usually water)."

Wet areas require some type of waterproofing or resistance to protect the structure. If they don't, "water will assuredly migrate through the grout, backer board or concrete substrate into the adjoining framing members," says Dave Gobis, a third-generation tile setter and executive director of the Ceramic Tile Education Foundation.

Unfortunately, there's no one method to controlling moisture, according to Shannon Woodmansee, Tile Council of North America's director of membership and public relations.

"There are so many variables," she says. "It depends on the room you're in, the mud you're using, the backer board, the tile. It's even different by region."

Despite the numerous variables for controlling moisture, tile industry professionals are able to offer universal advice to builders for keeping water from ruining tile applications.

Choose the right membranesThe first tip, says Joe Tarver, a 48-year tile business veteran and executive director emeritus of National Tile Contractors Association, is to understand that "waterproofing is a misnomer."

Anthony Flynn, senior technical services representative of C-Cure, knows there are misconceptions. "When you say 'waterproof membranes,' you're making a statement that water will not pass through this barrier."

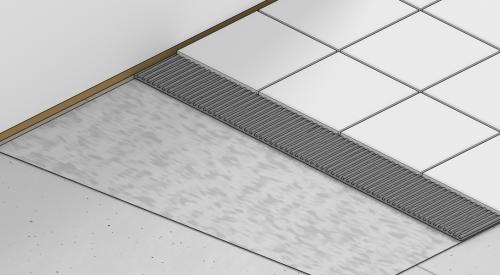

According to the tile council, there are two forms of waterproof membranes to use with vertical and horizontal thin- and thick-bed installations of ceramic tile:

- Single- or multicomponent membranes applied in liquid or paste form, which cure into continuous membranes

- Membranes applied in a flexible sheet form.

Some of these membranes have integral reinforcing fabrics for tensile strength and minor crack-bridging properties. Others are designed to be used as both waterproofing and tile-setting material.

"A single-component liquid application works best for builders," says Leigh Hightower, president of the Materials and Methods Standards Association and Texas Cement Products' director of business development.

The trend now, Flynn says, is to use membranes as cheap insurance. "In bathrooms, [people put the membrane on] the ceiling, floor and under plywood countertops, especially near the dishwasher, where moisture can get in and cause expansion," he says.

Select the right mortarChoosing the right mortar bed is also important and depends on the product. The tile council notes that manufacturers may require tile products be installed on a reinforced portland cement mortar bed applied over the membrane; applied directly on the membrane with a thin-set application of dry-set or latex-portland cement mortar; or thin-set to the membrane using a troweled application of the waterproofing membrane product.

Diligently Treat ShowersThe shower is the most obvious place builders need to be diligent about their tile applications.

Regarding shower pans, Richard Maurer, Nobles' director of marketing, says, "Not all trades will do a slope and not all codes will require it. So in the shower, a plumber may put the waterproofing on flat and not create a slope with packing mud."

Maurer warns of moisture in walls, especially enough condensation from an outside wall for mold to grow. He advises, "Make sure niches for soap or other uses are encased in extruded polystyrene insulation," which has excellent resistance to moisture absorption.

"Traditionally, a lot of water can create a crack in the grout, and then the mortar gets wet and you have a saturated bed," Maurer says. "It's a good idea to do a thin-bed waterproofing — put the membrane right on top of the slope so it's closer to the tile. In thin-bed installation, tile gets bonded to the membrane."

Use caulk for intersecting planes such as walls and floors, and at tub surrounds. "Due to structural movement with wood construction, you want caulk instead of hard grout in these intersections," Hightower says.

Select backer boards that workFor use on floors, walls and ceilings in wet areas, the handbook recommends cementitious backer board, cementitious coated foam boards, coated glass mat water-resistant gypsum backer board and fiber-cement underlayments. Fiber-reinforced, water-resistant gypsum backer board and underlayment should be used in limited water-exposure areas like foyers, kitchen countertops, bathroom floors and vertical surfaces, including tub surrounds without a shower head. All can be applied directly to wood or metal wall studs or over wood subfloors. Bonding materials vary.

Hightower steers builders toward cementitious board and away from green board (paper-faced, moisture-resistant wallboard) and noncoated or unreinforced gypsum. "Green and gypsum [boards] are not resistant to water," he says. "Even the gypsum associations don't recommend them for wet areas. It's an education process for the contractor and even tile contractors. You want something that won't deteriorate when wet."

Do it right the first timeHightower stresses that builders need to follow the handbook. "Most aren't familiar with the recommendations," he says.

But tile professionals warn builders about closely following manufacturers' instructions. "Today's highly engineered products may offer ease of application," Gobis says. "However, they are unforgiving of failure to follow instructions."

"I highly recommend that builders of multiple homes contact the manufacturers directly to find out what products to use rather than depending on a tile subcontractor who might use the cheapest product for the job," Hightower says.

Gobis offers more advice: "I would also strongly suggest that whenever you do use a manufacturer's waterproofing system, you use the complete system. Mixing installation systems and products is asking for disaster given the highly engineered products used today."

| Author Information |

| Jennifer Block Martin is a San Francisco-based writer whose articles have appeared in Custom Builder, Better Homes and Gardens' Special Interest Publications, Sunset and Women's Day Home Remodeling & Makeovers. |